VIBRATION CONTROL

Vibration control is divided into two (2) different studies knowing:

- Vibration Control up to 25 Hz so called vibrations,

- Structural Optimalization from 25 Hz and up.

For both studies Silent Line is using Finite Element Analysis (F.E.A) computer software. The aim of using this computer software is to avoid annoying vibrations | resonance and to achieve comfort class vibration levels as shown in the table below.

|

Table A11 Yacht Owner and Guest Areas Frequency weighted r.m.s. maximum values in mm/s from 1 Hz to 80 Hz |

||||||

|

Locations: |

Comfort rating number (crn)

|

|||||

|

|

In harbour condition |

Transit condition |

||||

|

|

1 |

2 |

3 |

1 |

2 |

3 |

|

Accommodation |

0.5 |

1.0 |

2.0 |

0.8 |

1.5 |

2.5 |

|

Outdoor Recreation Areas |

0.5 |

1.0 |

2.0 |

1.5 |

2.5 |

3.0 |

|

Navigation Bridge |

- |

- |

- |

1.0 |

2.0 |

3.0 |

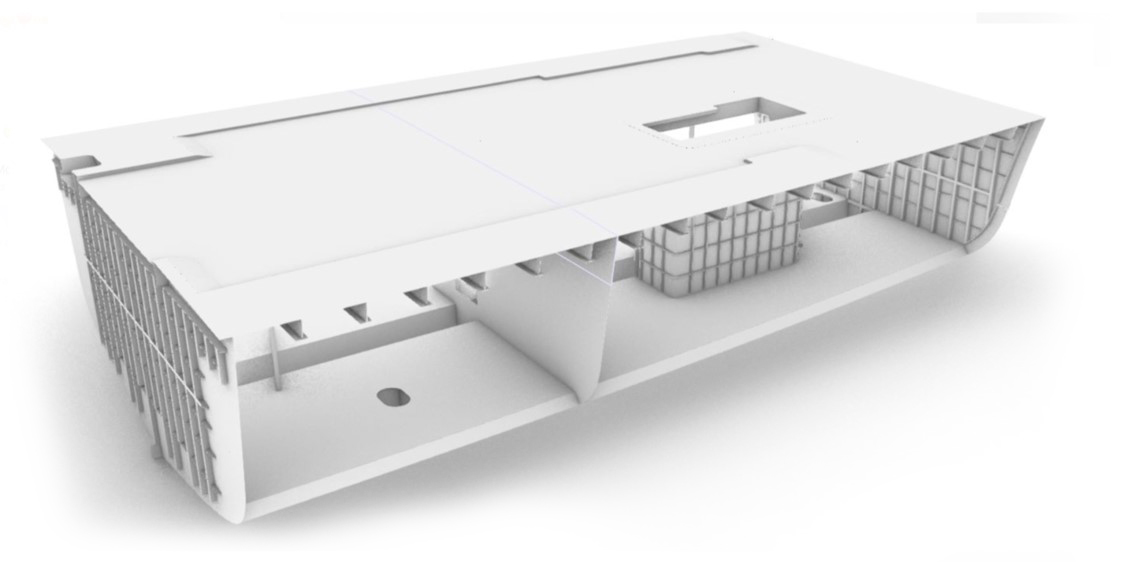

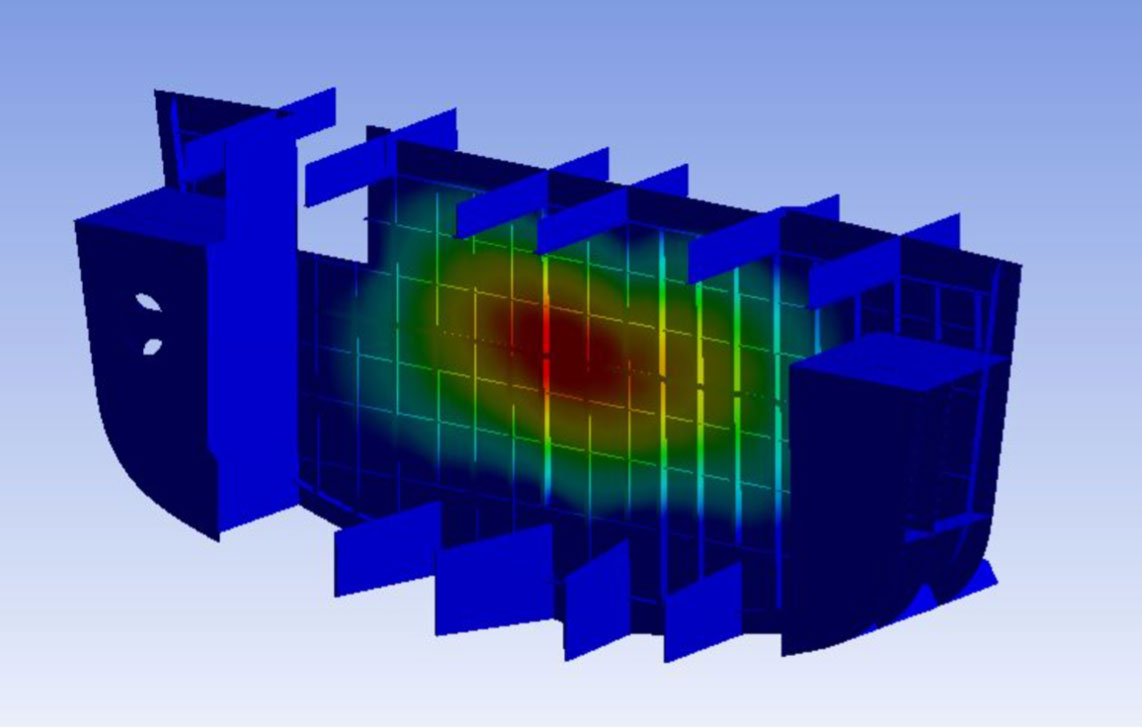

The first step is to build a model as shown below using structural drawings, material properties and add additional load or entrained water etc. if present.

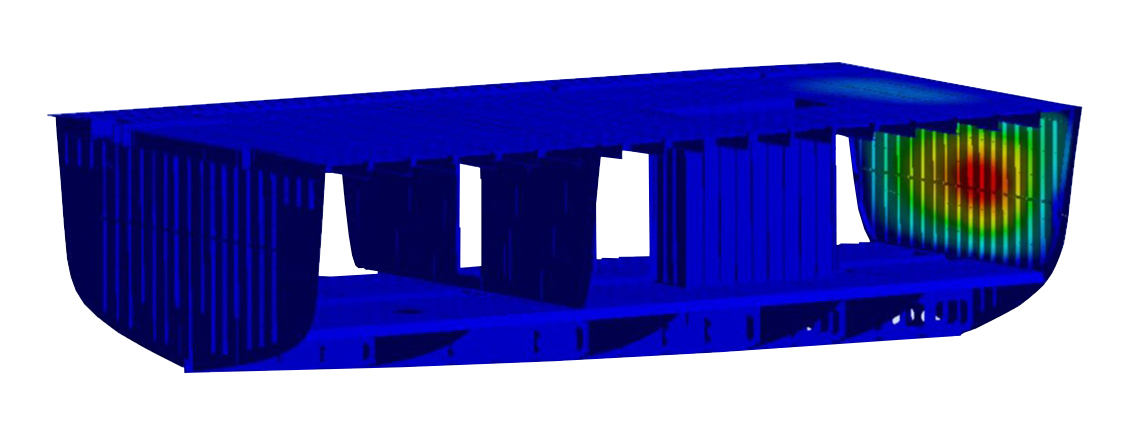

Ones the model is completed it can be used to calculate the most important natural frequencies and mode shapes as shown below.

66.225 hz at Bulkhead Fr.33

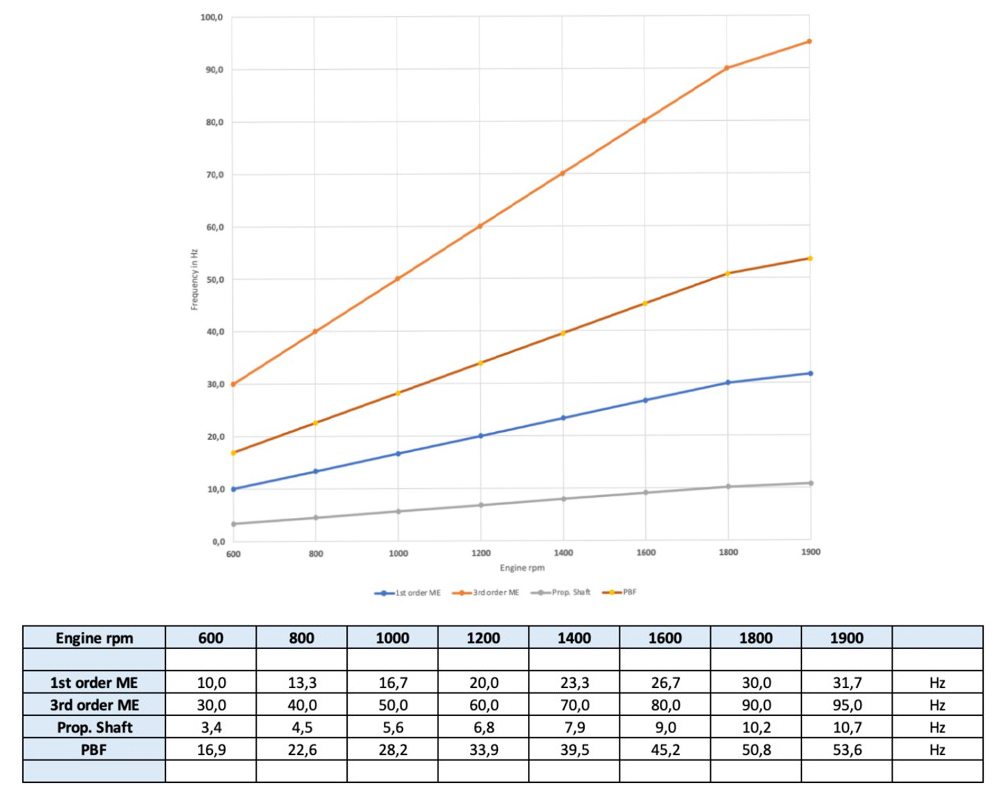

The next step is to investigate the calculated natural frequencies and mode shapes in which all natural frequencies below 15 Hz must be avoided as they are too low from vibration point of view (vibrations can easily occur by means of limited excitation forces) and natural frequencies close to or equal to main disturbing frequencies must be avoided as well as they cause resonance.

Structural optimalization:

Structural optimalization is mainly related to radiated structure-borne noise (becoming air-borne noise). If structures such as bulkheads are critical from vibration point of view additional stiffeners are required to reduce radiation, sound deadening can be added as well however it is extremely important to create an optimum structure prior to add sound deadening and insulation materials.

VIBRATION CONTROL RELATED PRODUCTS:

PRODUCT DETAILS & PDF'S

Silent Line is working closely together with Pyrotek for many years already mainly providing noise and vibration related studies for the Marine sector however in 2022 we extended our cooperation for the Turkish market related to the Industrial sector. Pyrotek offers a wide range of engineering-based products as shown below. Upon request of the client Silent Line offers in addition onsite supervision | consultancy and trouble shooting.

Silent Line is working closely together with Pyrotek for many years already mainly providing noise and vibration related studies for the Marine sector however in 2022 we extended our cooperation for the Turkish market related to the Transportation sector. Pyrotek offers a wide range of engineering-based products as shown below. Upon request of the client Silent Line offers in addition onsite supervision | consultancy and trouble shooting.

Silent Line in close consultation with Getzner and Pyrotek is offering Innovative Engineering based products and solutions. This can be either for offices in which Silence and Comfort is important to increase the efficiency of the employees or at Luxury apartments in which neighbors can disturb your privacy or rotating machinery such as generator sets, pumps, air conditioning etc.