FOREWORD:

Silent Line Group, with more than 30 years of experience in the field of noise and vibration control on board Luxury Yachts, is THE leading and most innovative company in the world offering tailor made solutions related to

FIRE PROTECTION.

By means of this newsletter we present to you our concept of a SOLAS approved sound reducing floating floor system, including easy to install height adjustable floor gridwork.

The system can be extended using B15 approved free standing partition walls with additional sound proofed options.

FLOOR GRIDWORK:

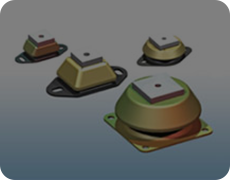

The base of the floating floor is a stainless steel or aluminium height adjustable gridwork based on longitudinal and transverse supports, as shown below, with a 300 x 600 mm spacing or 600 x 600 mm spacing.

The floor gridwork is levelled, on the top as shown on the right, using the height adjustable feet as shown on the right as well.

Ones the floor gridwork is installed and levelled, glue is injected from the top of the adjustable feet to secure the floor gridwork from any movement.

BISCO:

Material:

Bisco 1.3 M 0940

Weight:

ca. 380Kg/m3

Certification:

Low flame spread en smoke & toxicity: IMO Res. MSC 61 (67)

Available dimensions:

40 mm wide (other width on request)

Thickness:

9 mm

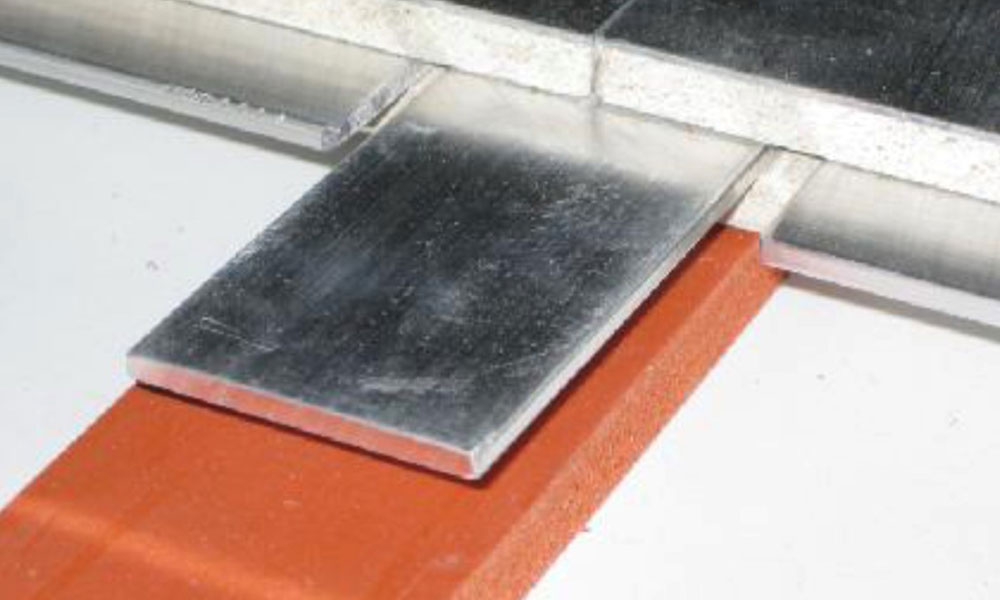

BISCO, as an elastomer, is the base to create a floating floor concept.

Floating floor systems are installed on board Luxury Yachts and Commercial Vessels to avoid annoying vibrations in accommodation areas.

THE CONCEPT OF A FLOATING FLOOR:

Pending on the type of BISCO, various stiffnesses are available, and the dynamic load along with the dimensions of the floor gridwork (300 x 600 or 600 x 600 mm) a natural frequency of the system will occur.

It is extremely important that this natural frequency is known prior to install the floating floor. An interference between the natural frequency of the floating floor and disturbing frequencies emitted by machineries must be avoided at all times.

If the natural frequency of the floating floor interferes with a disturbing frequency (ratio 1:1) resonance will occur causing serious vibration problems.

NC / SR B15 FLOOR:

Product:

Druma-floor NC/SR

Noise reduction:

RW 34 dB

Thickness:

17 mm

Sizes:

2400 x 800 mm

System weight:

17,8 kg/m2

Core material:

Calcium silicate, rot, moisture and impact resistant

Certification:

Class B-15 according to IMO Res. 754 (18)

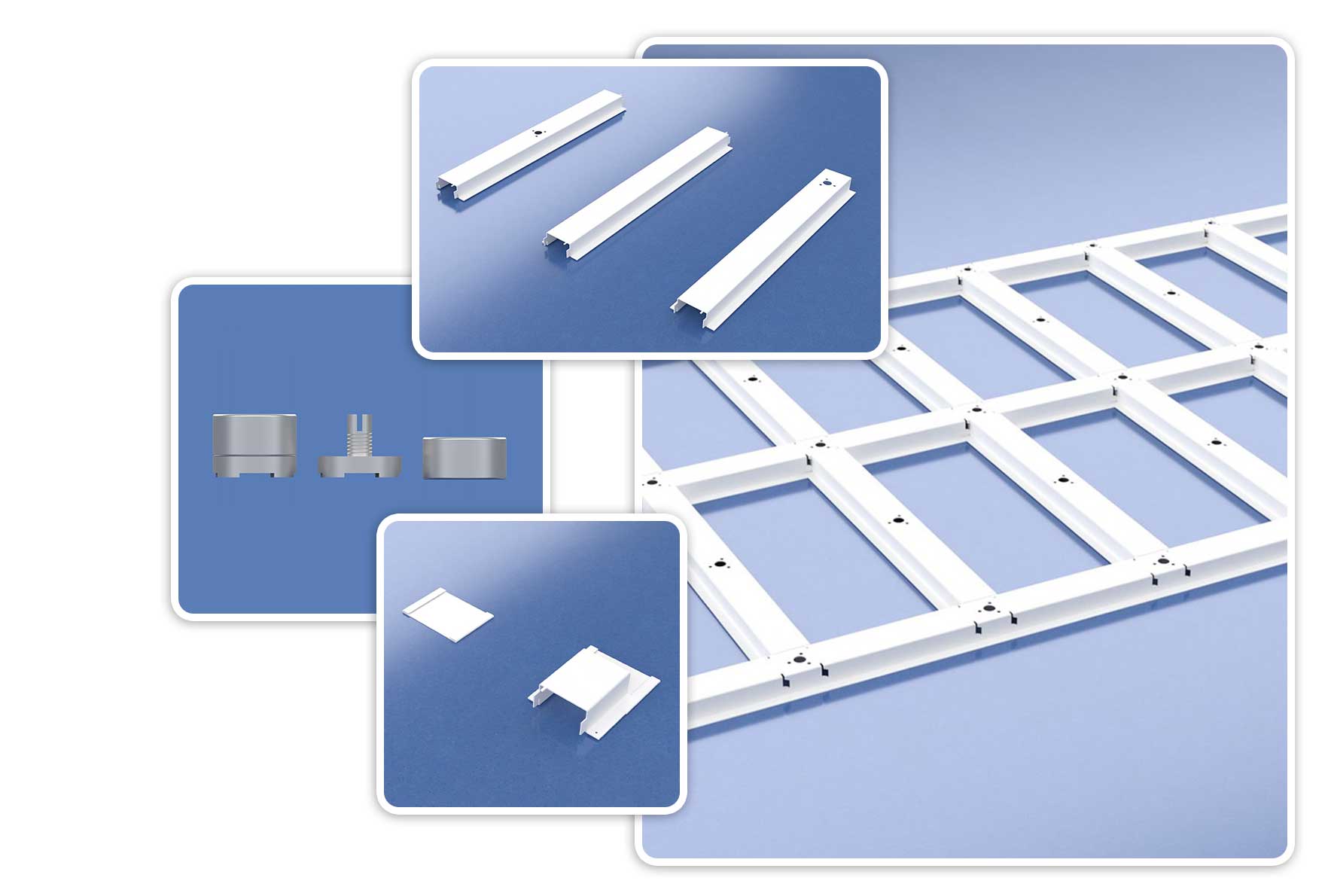

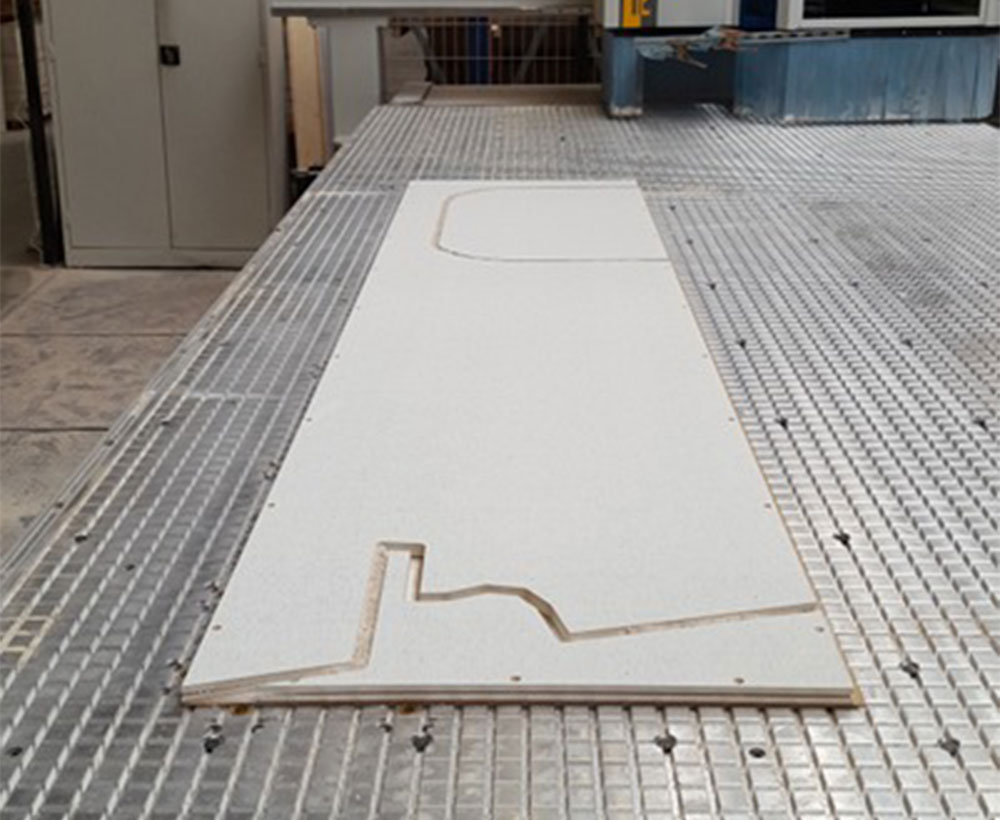

The Druma-floor NC/SR is a Class B15 IMO approved floor panel.

The outer skins are 0.8 mm aluminium with a calcium silicate core material. Aluminium strips are used, see images on the right, to connect and secure the floor panels.

DRUMAFLOOR NC:

Thickness:

17 mm

Sizes:

2400 x 600 mm

System Weight:

20 kg/m2

Noise reduction:

RW 34 dB

Certification:

Non-combustible; volgens IMO Res. MSC A.799 (19)

Core material:

Calcium silicate, rot, moisture and impact resistant

Application:

Floor system *, to be installed on trusses or rock wool

This panel is constructed from a calcium silicate core, with an HPL plate on both sides, with a sanded surface.

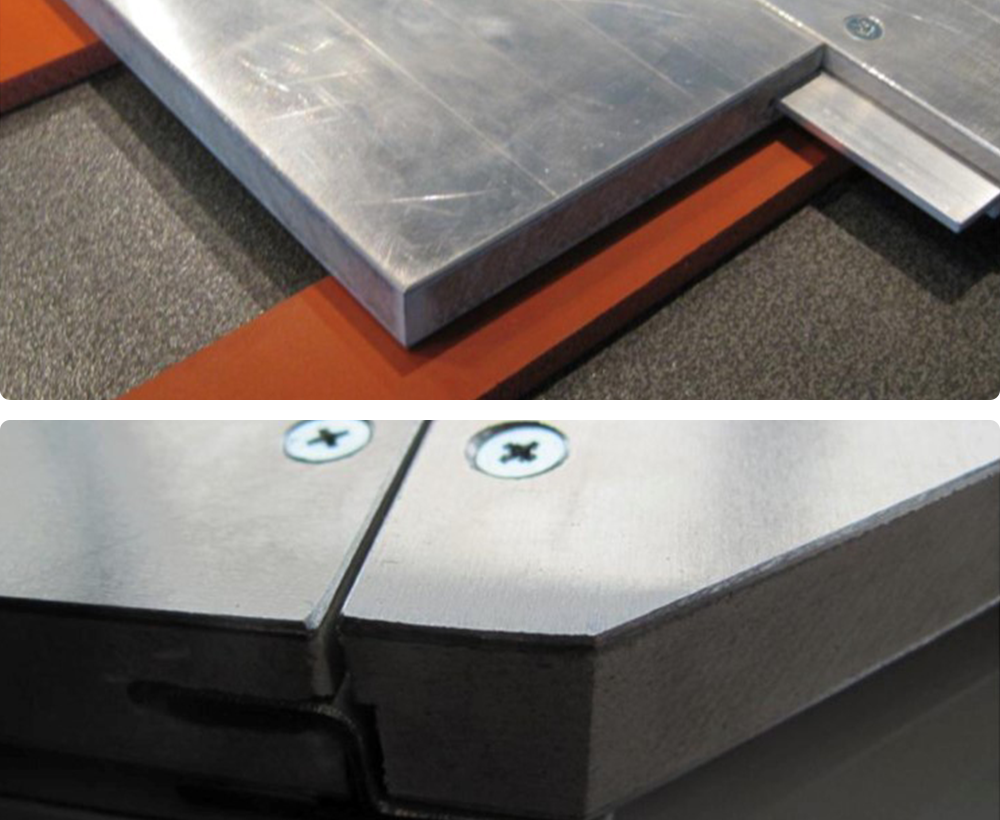

The panels are provided with a groove all around and are mounted by means of an aluminum spring and fixed with steel screws with countersunk head.

Product features

- Complies with IMO Res. MSC A.799 (19),

- Floating floor in combination with Bisco or rock wool,

- Easy installation,

- Excellent mechanical properties,

- Low weight.

Installation and processing

If the panels are placed on rafters, we recommend a rafter distance of 40cm * and they must be sufficiently aligned. If the floor panels are installed on stone wool, the steel sub-floor must be sufficiently flat. The panels are supplied with heavy plastic corner protectors and are pre-drilled all around, with the holes countersunk. After the panels and the aluminum springs have been installed, only the holes need to be drilled (drill diameter 4.5 mm), after which the panels can be fixed with the supplied thread-forming screws (M 5×12 mm). It is recommended to cover the floor with hardboard plates afterwards, or if the floor is subjected to extreme loads during construction, underlayment plates to prevent damage. We also supply CoverGuard on request; a flame-retardant plastic protective film with a non-slip structure, with which the whole can be covered (supplied on a roll (110 x 0.91 m)). This means that sparks from welding, burning or grinding can no longer be a hazard.

* At a frame spacing greater than 40cm, a higher floor load than usual or where a higher system weight is required, Drumafloor NC can be used in combination with the Druma basicfloor NC.

PLURATECT MARINE LIGHT:

Colour:

White core with Promat Blue finish

Surface conditions:

Smooth

Normal density (tolerances):

500 (±10%) kg/m3

Reaction to fire:

None-combustible according to MED certificates module B and D - ask to Drumarkon more information

Class divisions:

B15 Bulkhead:19mm | C: 12.5 - 19mm

Panels joint:

Solid Spline "C"-Spline or Omega-Spline

Termal conductivity:

0.25 W/mK

Compress resistance:

>2.4 MPa

Young Modulus (MD) (EN 15283-1):

1500 MPa

Bending strength (MD) (EN 15283-1):

5.5 MPa

Alkalinity - Surface / Core:

6/8.4 pH

Certification:

Non Combustible

Acoustic Properties

Tickness:

19mm - 19+19mm (+10mm air gap)

Rw Index (ISO 717/1):

27 - 36 dB

Standard Dimensions

Tickness (tolerances):

12.5;19 mm (+/- 0.3)

Length (tolerances):

2500 - 2800 - 3050 mm (+/- 0.5)

Width (tolerances):

1220 mm (+/- 0.4)

PLURATECT MARINE LIGHT is a versatile, lightweight, non-combustible fire protection board ideal for installation and applications in the marine market for B and C Class divisions

Properties

- Smooth and consistent surface

- Suitable for bonding laminates

- High ductility withstanding high deformations

- Easy to process and install

- 100% recyclable

Workability

PLURATECT MARINE LIGHT can be cut using normal cutting tools or by using circular blades. When bonded with HPL specific blades must be used. During cutting operations use personal protective equipment.

Waste disposal

Refer to local legislation. If not available. The board is not classified as a dangerous subtance and so no special provisions are required regarding the carriage and disposal of the product to landfill.

Storage

Store on a flat surface, in a dry area.

Area of application

- B and C Class constructions

- Fire-rated linings and bulkheads

- Public areas, standard and luxury cabins

- Non-combustible furniture

PROMASIL MARINE:

Noise reduction:

RW 27 dB (22 mm thickness glued with HPL)

Thickness:

22-50 mm

Size:

2500 x 600/1000 mm

Density:

285 kg/m3

Certification:

C class and B15 class (23mm thickness)

Application:

Bulkhead and furniture

Basic material:

Calcium silicate, rot-, moisture- and impact resistant

Advantages

High temperature resistant

Chemical and moisture resistant

Good workability

Minimal gas and smoke emission (in case of fire)

Applications

B15 Class partitions

Furniture

B15 PARTITION WALLS:

Material:

Promarine

Weight:

640 Kg/m3 - 450 Kg/m3

Dimensions:

2440 x 1220 mm

Thickness:

640: 9.7mm, 12.7mm, 15.9mm, 19.1mm, 22.2mm, 31.8mm

450: 16mm, 19mm (Special thickness on request).

Surface:

Bare or covered with HPL

Application:

Wall, Ceiling, Furniture

Calcium Silicate boards in various thicknesses, and densities, with HPL finishing are offered as IMO approved class B15 panels.

PARTITION WALLS:

The panels are placed in U-profiles, on top of the Druma-floor NC/SR and are free standing. The panels are connected by means of strips as shown on the left.

Pending on the acoustic privacy requirements, Rw for cabin-to-cabin noise, sound reducing panels can be added to achieve the requirements of the customer.

Silent Line is able to perform cabin-to-cabin noise calculations and design and supply custom build innovative solutions.

HULL | BULKHEAD LINERS AND CEILING PANELS:

The free-standing class B15 panels can also be used for hull and bulkhead liners or ceiling panels.

PROMAGUARD:

Material:

Promaguard

Thickness:

6mm / 10mm / 15mm

Dimensions:

1200 x 600mm

Variant:

Aluminium / standard

Certification:

A and B Class Fire Protection

PROMAGUARD® is a new generation product used for passive fire protection and thermal insulation. Formulated with exclusive mineral and non-fibrous materials based on microporous and PROMAXON technologies, PROMAGUARD® provides efficient solutions for ships and yachts that save weight and reduce thickness up to four times compared to traditional materials and solutions.

QUALITY ASSURANCE

Promat products are manufactured under strict quality control systems to ensure our customers receive materials made to the highest standards. Working according to these standards means that all activities that affect quality are recorded in written procedures. All materials and their use are systematically and thoroughly checked. Test equipment is regularly checked and referred back to national standards. The information in this data sheet is based on actual testing and is believed to be typical of the product. However, no guarantee of results is made as the conditions of use are beyond our control.

Advantages

Non-combustible

Very lightweight

Contains no fibers

Flexible and easy to install

Excellent thermal conductivity

Applications

A Class construction

Bulkheads and Decks

Trunks

Thermal insulation on exhaust systems

THERMAL CHARACTERISTICS

PROMAGUARD® has the lowest thermal conductivity compared to most traditional insulation products available on the market. The graph shows that 10 mm PROMAGUARD® (in relation to density and temperature) produces a reduction in the radiated heat and an insulation that would be achieved with 50 mm of typical fiber material. Therefore, PROMAGUARD®, weighing 2.4 kg / m2 for a thickness of 10 mm, can deliver the best performance and achieve A60 class fire protection.