Numarine 37XP

Silent Line | Enjoy Your Luxury in Silence

INTRODUCTION:

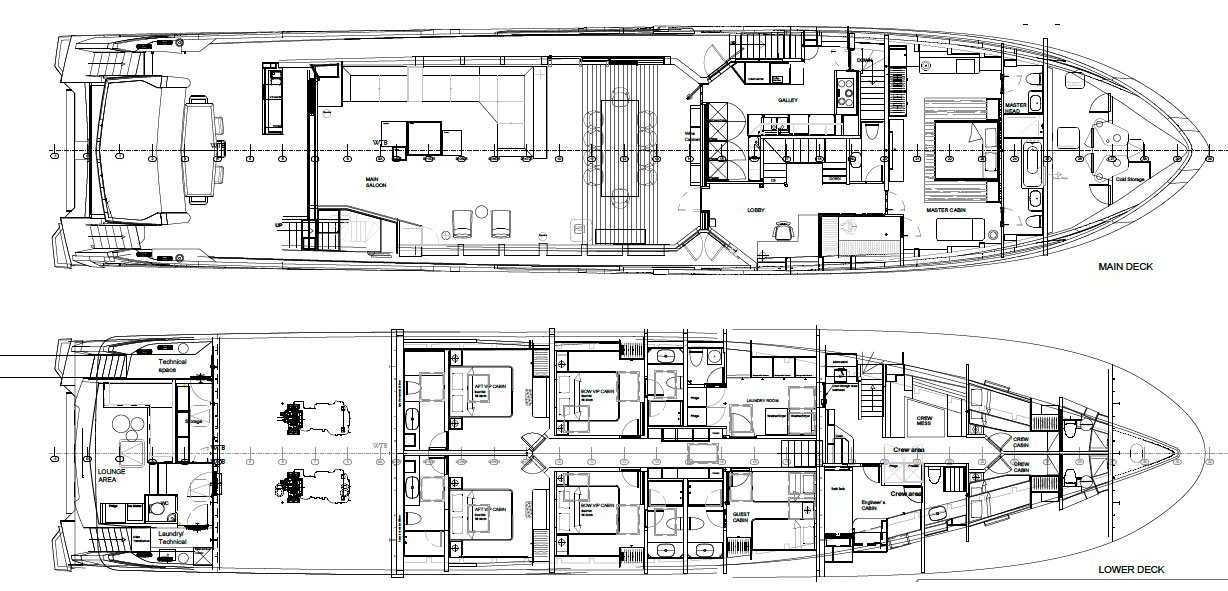

As Silent Line we did many luxury Yachts in the range between 25 up to 50 meters in length, however we would like to point out the successful Numarine XP edition as this Yacht contains most of the latest technologies in the field of noise and vibration control.

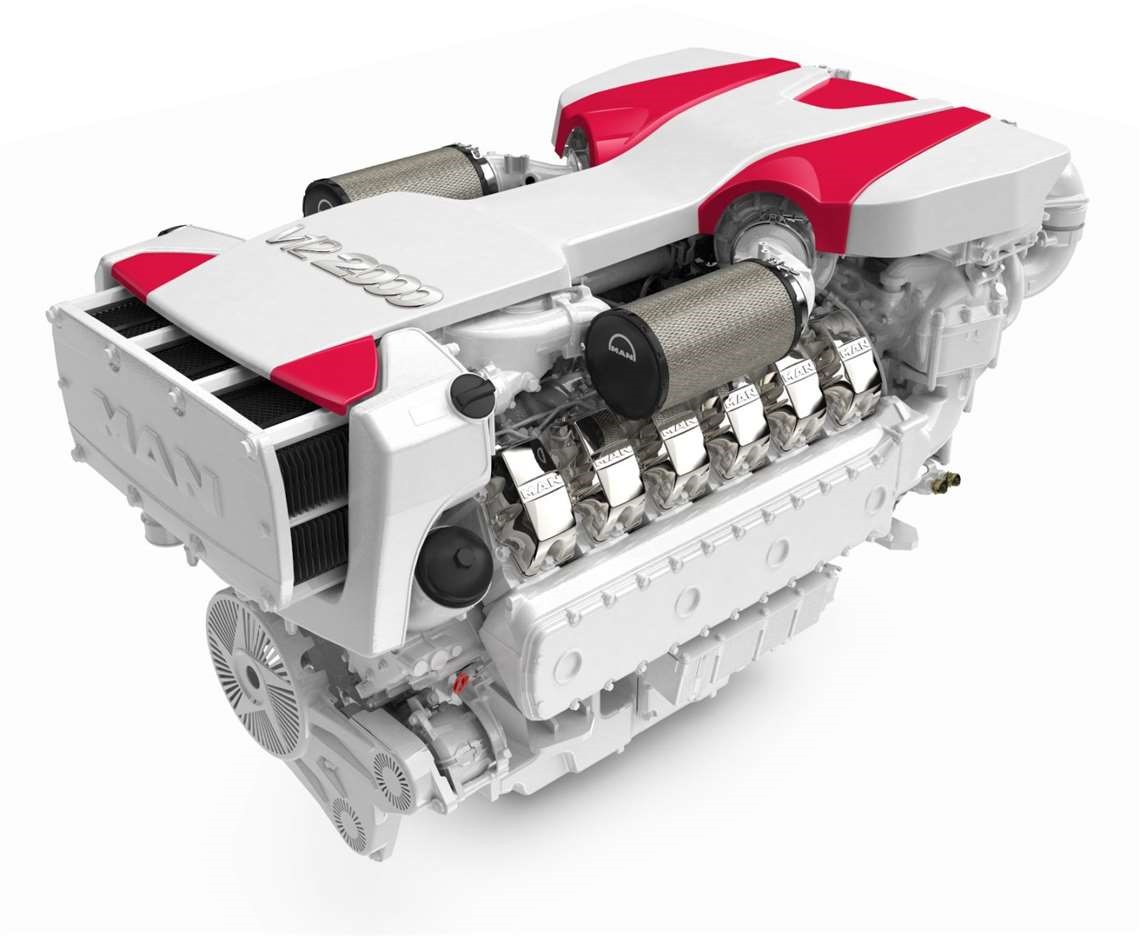

PROPULSION TRAIN:

The propulsion train, main engine and gearbox, are producing both airborne noise and structure borne noise (vibrations), which must be reduced in order to achieve comfortable noise and vibration levels in the accommodation areas and outer deck areas.

Before we go into details what has been done onboard this Yacht, we would like to point out what we achieved for both Cruising speed and Anchor condition.

Measured noise levels at cruising speed

- Ship speed : 9 knots

- Engine speed : Both engines 1100 rpm

- Generator set : 1 generator set running

- Stabilizers : Operational

- HVAC : Running at fan speed 1

|

Cabin | Room |

Measured level in dB(A) |

Notes: |

|

|

|

|

|

Cabin | Room on Lower Deck: |

|

|

|

Engine Room |

96.8 |

-- |

|

VIP cabin SB aft |

40.2 |

-- |

|

VIP cabin PS aft |

39.5 |

- |

|

Guest cabin SB mid |

35.1 |

- |

|

Guest cabin PS mid |

34.1 |

- |

|

Guest cabin SB front |

32.3 |

- |

|

Crew Messroom PS |

44.5 |

- |

|

Crew cabin SB aft |

38.6 |

- |

|

Crew cabin SB |PS front |

37.5 |

- |

|

|

|

|

|

Accommodation on Main deck: |

|

|

|

Saloon |

39.0 |

- |

|

Dining |

40.4 |

- |

|

Galley PS |

37.5 |

- |

|

Master Stateroom |

30.1 |

- |

|

|

|

|

|

Accommodation on Upper deck: |

|

|

|

Lounge | Bar |

33.7 |

- |

|

Captain’s cabin PS |

38.1 |

- |

|

Wheelhouse |

44.1 |

- |

Table 1: Measured noise levels in dB(A)

- Measurements in the center of the cabin | room at 1.6 meter above floor level

- All doors are closed, carpet in the accommodation areas was installed

- Background noise is minimum 10 dB(A) less than the measured noise levels as indicated in the below table

- Household equipment is not running as well as abstraction fans in the Galley

- Rudder angle < 2 degrees

Measured noise levels at anchor condition

- Generator set : 2 generator sets running (Load 24 and 25 kW)

- Stabilizers : Operational

- HVAC : Running at fan speed 1

|

Cabin | Room |

Measured level in dB(A) |

Notes: |

|

|

|

|

|

Cabin | Room on Lower Deck: |

|

|

|

Engine Room |

79.1 |

- |

|

VIP cabin SB aft |

28.7 |

- |

|

VIP cabin PS aft |

29.0 |

- |

|

Guest cabin SB mid |

29.4 |

- |

|

Guest cabin PS mid |

29.4 |

- |

|

Guest cabin SB front |

29.5 |

- |

|

Crew Messroom PS |

38.7 |

- |

|

Crew cabin SB aft |

29.2 |

- |

|

Crew cabin SB |PS front |

29.3 |

- |

|

|

|

|

|

Accommodation on Main deck: |

|

|

|

Saloon |

33.3 |

- |

|

Dining |

38.7 |

- |

|

Galley PS |

38.3 |

- |

|

Master Stateroom |

26.2 |

- |

|

|

|

|

|

Accommodation on Upper deck: |

|

|

|

Lounge | Bar |

32.2 |

- |

|

Captain’s cabin PS |

28.3 |

- |

|

Wheelhouse |

42.4 |

- |

Table 2: Measured noise levels in dB(A) at ANCHOR:

- Measurements in the center of the cabin | room at 1.6 meter above floor level

- All doors are closed, carpet in the accommodation areas was installed

- Background noise is minimum 10 dB(A) less than the measured noise levels as indicated in the below table

- Household equipment is not running as well as abstraction fans in the Galley

What has been done by Silent Line:

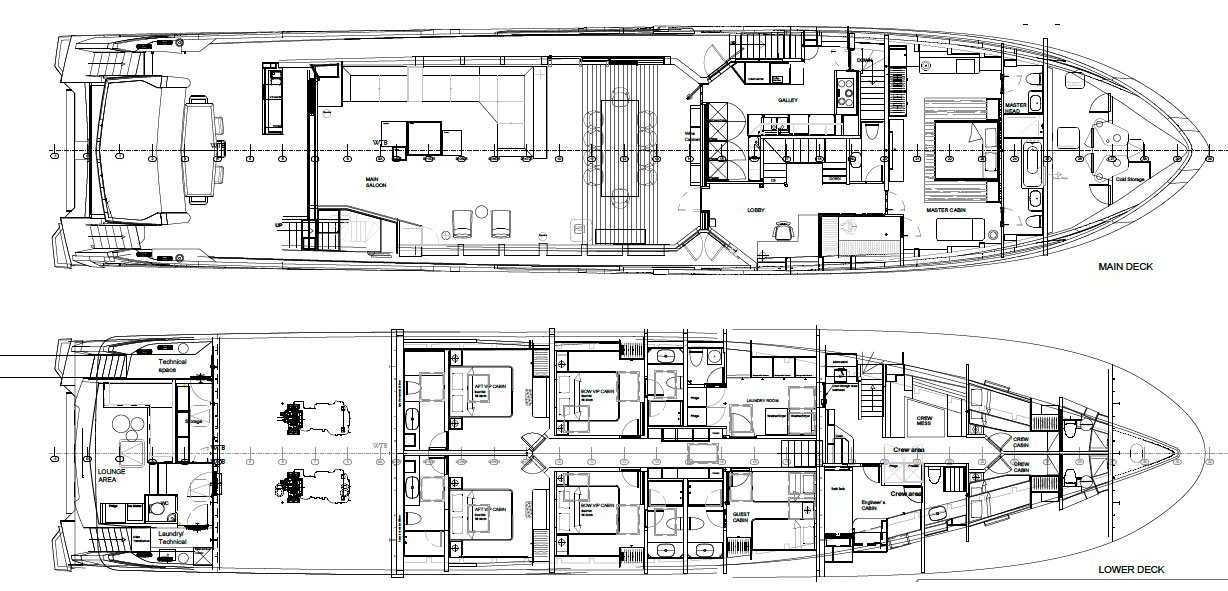

Main engine and gearbox:

The shaft line does include a thrust bearing and highly flexible coupling, see flexible coupling chapter, which means that the elastic mounting system for engine and flanged gearbox can be relative soft (flexible). We use the SLP-MOUNT IM 2500 – C series as shown below.

Gearbox noise:

The gearbox is flanged to the main diesel engines using the same SLP-MOUNT IM 2500 C series mounts, this gives us the required amount of isolation to create comfort onboard this Yacht.

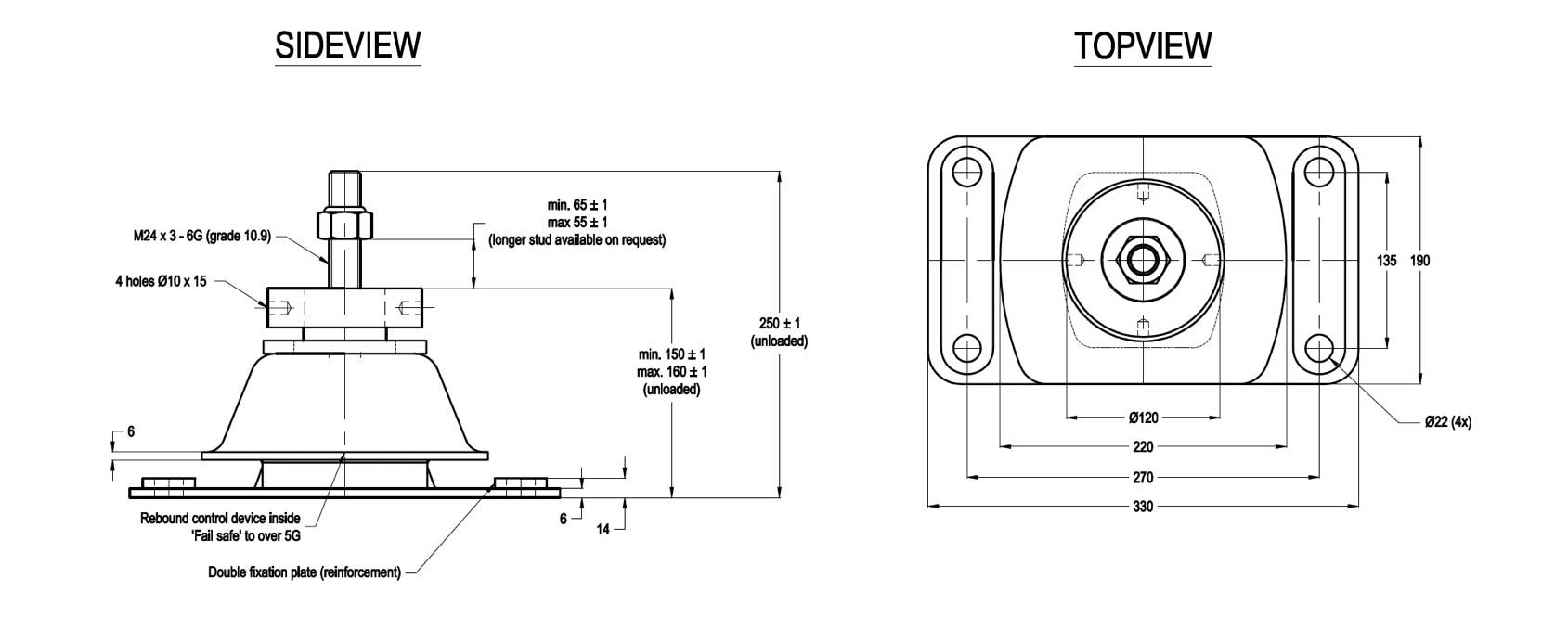

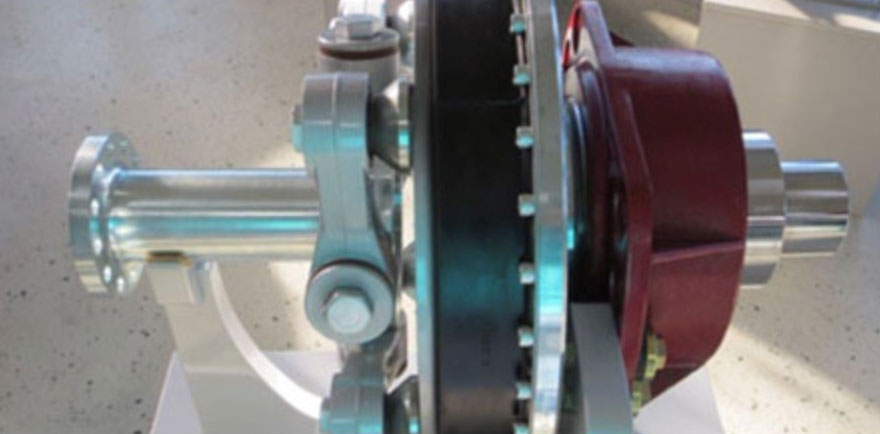

Flexible coupling between gearbox and propeller shaft:

The above shown highly flexible coupling is ideal as it contains:

- A link (arm) system to give us flexibility,

- A rubber element to isolate engine | gearbox noise from the propeller shaft,

- A trust block (red block on the right) to absorb the forces emitted by the propulsion propellers.

Generator sets:

Generator(s) are an important sound source mainly at anchor (in port) condition. Air borne noise, up to approx. 75 dB(A) for generator sets placed in a proper canopy (sound shield), is not a main issue if the engine room is well insulated (see chapter on engine room insulation).

In most cases structure borne noise is the dominant sound path, generator sets do have an elastic mounting system however in most cases the mounts are relative stiff which means limited isolation of structure borne noise emitted by the diesel engine.

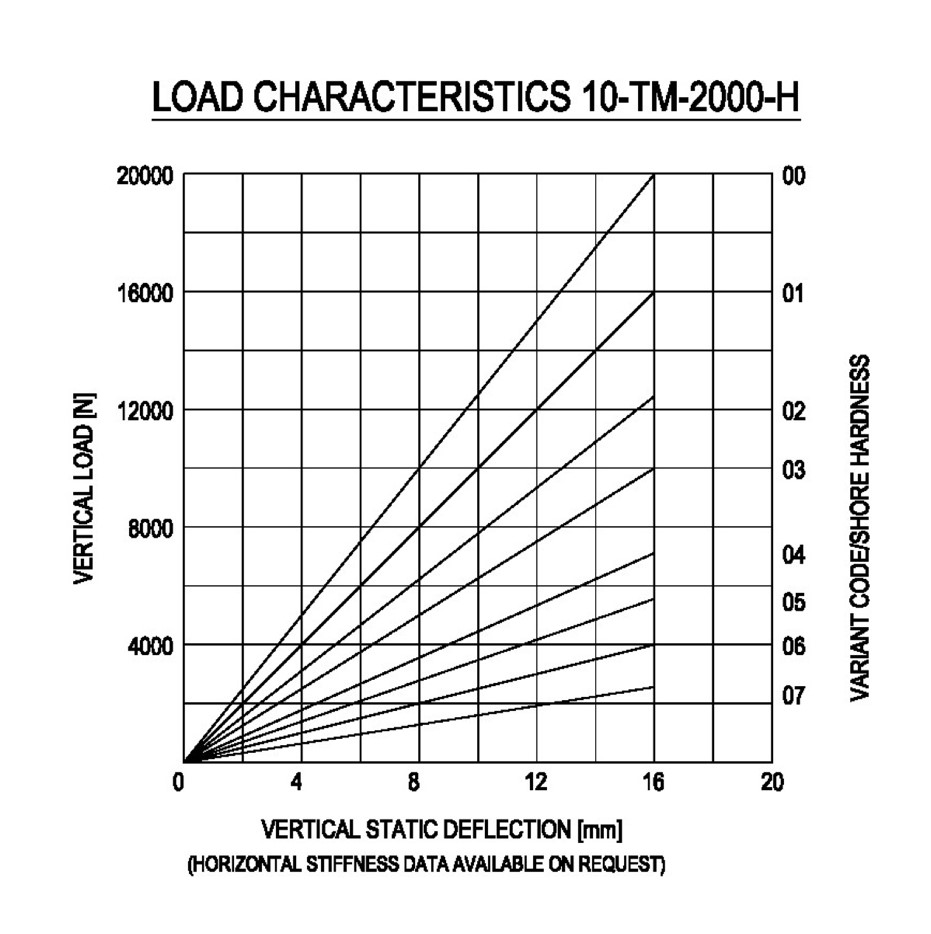

To solve this issue, we as Silent Line, recommend high volume additional mounts (SLP-MOUNT TM series) to be installed underneath the sub frame of the generator set. The benefit of the high-volume mounts, static deflection up to 10 mm, is that an additional heavy sub frame is avoided. With a standard double elastic mounting system, a heavy subframe is required to make the system work properly. By using high volume mounts, as shown below, such as heavy sub frame is not required.

Various rubber stiffnesses are available as shown in the above graph, Silent Line will do the necessary engineering studies to provide you with the best solution.

A stiff structure underneath the secondary elastic mounting is always required to achieve the best results, contact us if you have questions related to the structure you are using onboard your Yachts.

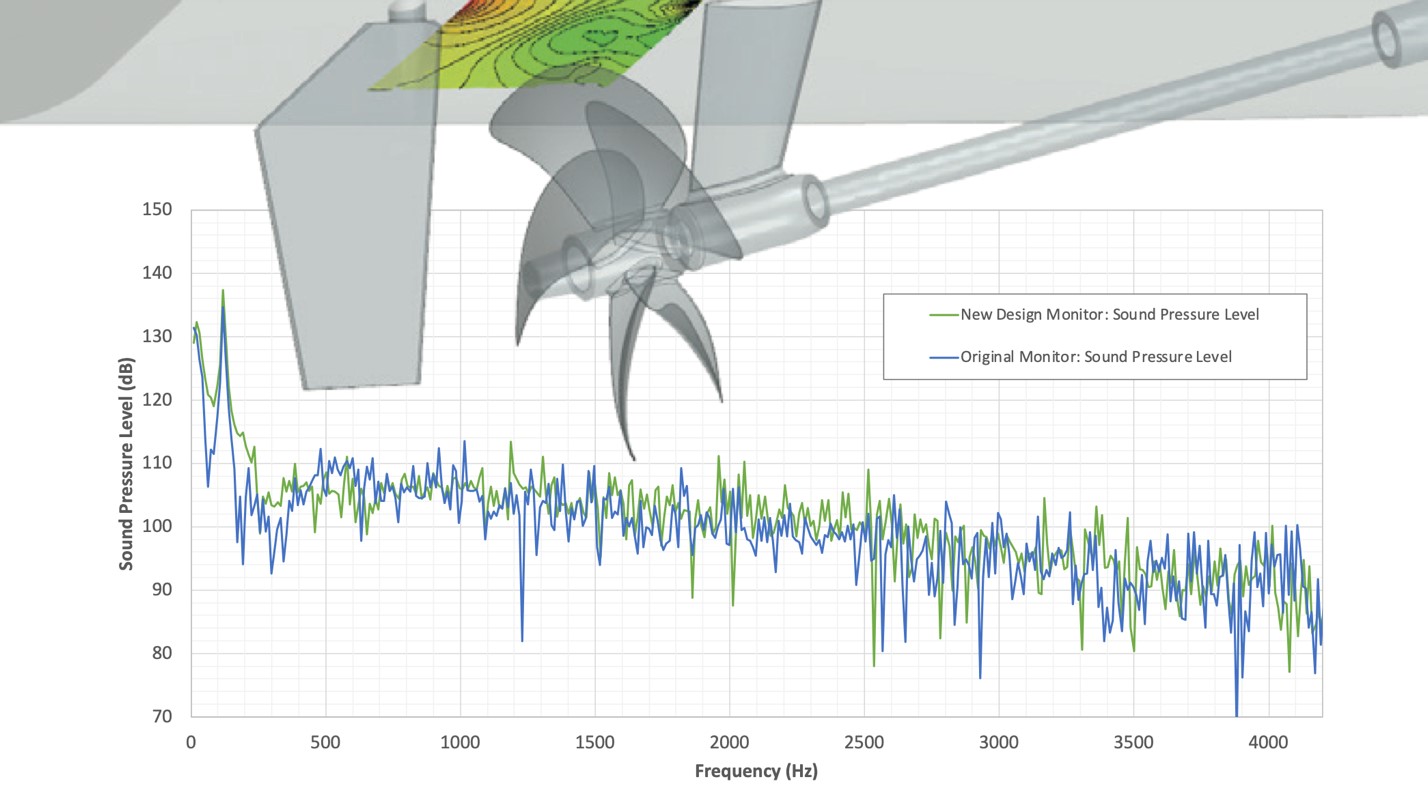

Propulsion Propellers:

Pressure fluctuation, forces emitted by the propulsion propellers, is an important sound source onboard Luxury Yachts. Onboard most nowadays Yachts we have a beach area above the propulsion propellers however in the “old days” we have Guest Accommodation above the propellers.

Important parameters related to propulsion propellers are:

- Number of blades,

- Blade area ratio,

- Skew,

- Tip unloading,

- Finishing of the blades,

- Vertical clearance between propeller tip and hull plating

For steel and aluminium hull structures we apply a constrained layer sound deadening material (SLP-COMP) and for GRP we offer SLP-CLD tiles or SLP-MASS which must be applied on top of the hull plating above the propellers. The area must be equal to the propeller diameter in square.

Engine room insulation:

A proper engine room insulation package is required mainly to block air borne noise emitted by the main diesel engines. As we prefer to keep the noise inside the engine room, perforated plate must be avoided. We prefer to use closed aluminium or steel sandwich plates (SLP-SONIC) as shown below.

.

DI-BOND or ALUCO-BOND must be avoided as well, even as they are closed plate sandwich panels, they are very poor on noise reduction and mainly used in the building industry as decorative panels.

Between the structure and the above mentioned SLP-SONIC finishing plates we prefer to use a combination (sandwich) of isolation materials to reduce noise transmission in a frequency range from 31.5 Hz up to 8 kHz.

This can be achieved by using two outer layers of Rockwool or Glass wool with a mass layer in between (SLP-MASS). Thickness and density is pending on the requirements for fire protection.

Alternative fire resistant (non-combustible) are available as well, please contact us if you have questions.

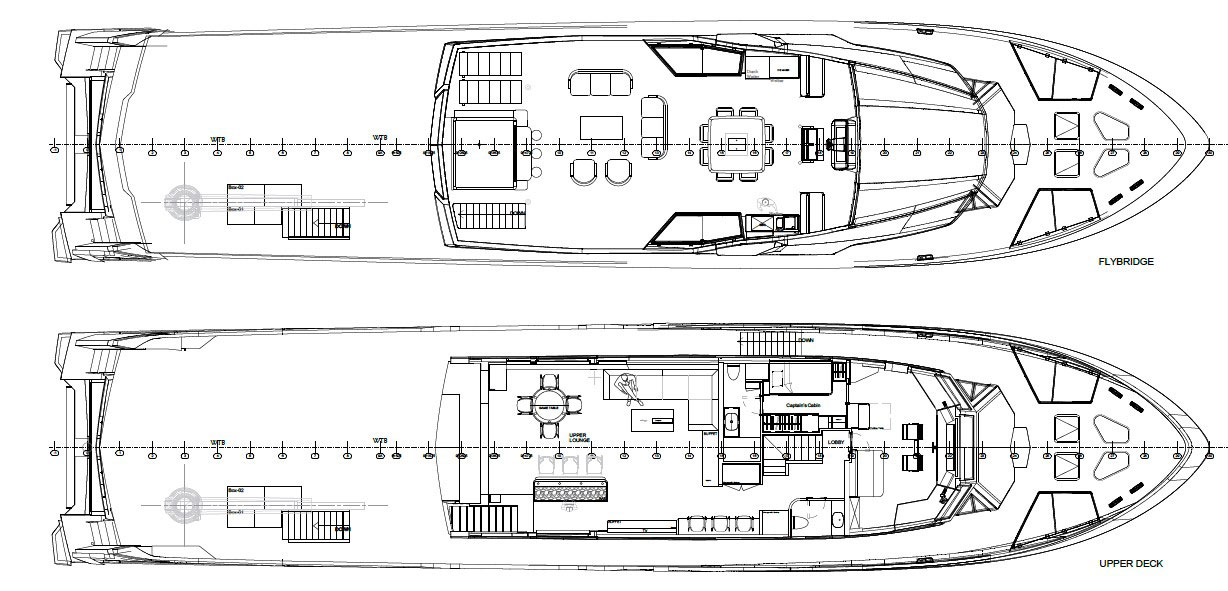

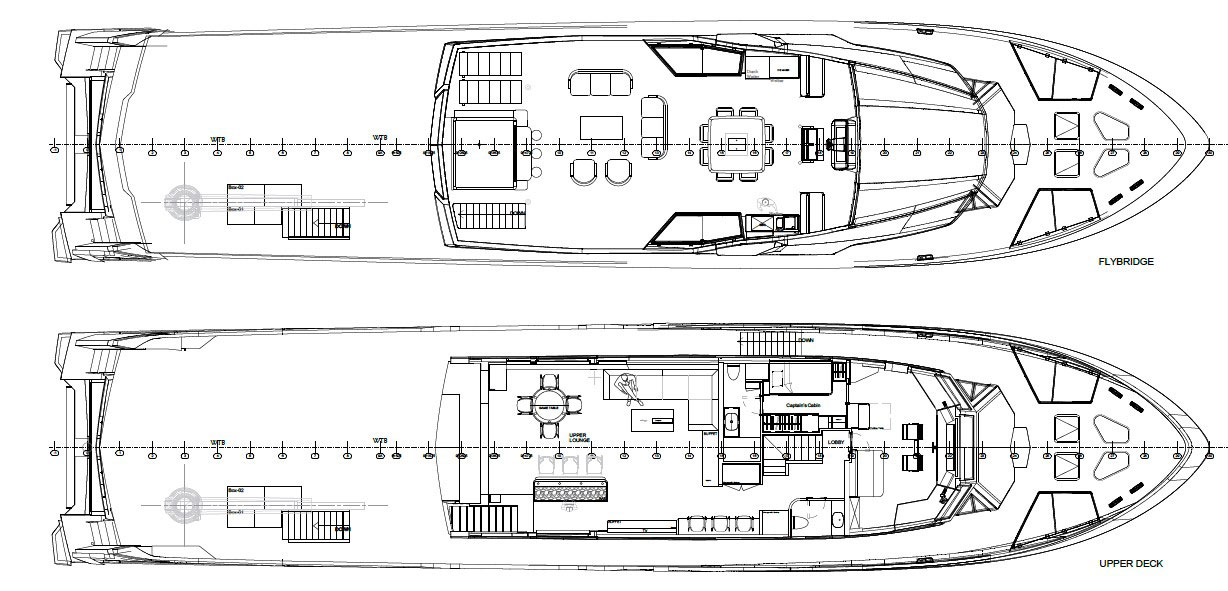

Accommodation areas:

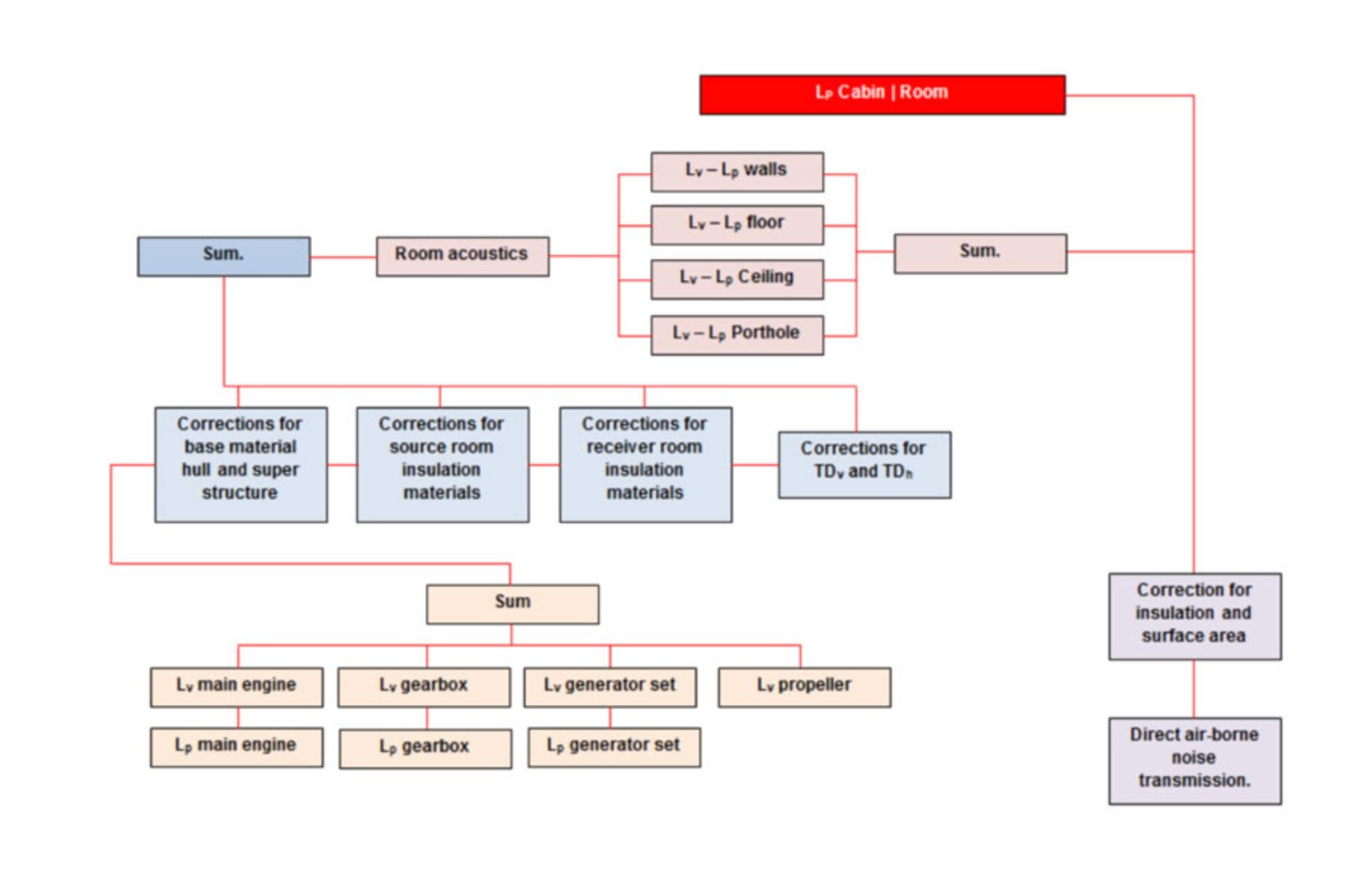

Critical areas are the Guest areas forward of the engine room and the Salon area above the engine room. Radiated structure borne noise from the portholes is the dominant sound path, Silent Line is using comprehensive computer simulation models for both noise prediction as well as determining what is the most important sound source and sound path.

The most important sound path in the Salon is (1) Direct air borne transmission from the engine room, (2) Direct air borne noise transmission from the engine room trunks and (3) noise transmission through the aft sliding door and radiation from the large windows in the Salon.

Aft Guest accommodation:

Structure borne noise emitted by the main sound sources such as main diesel engines, propellers and generator sets are reduced to a minimum which is very important (reduce the noise levels at the source as much as possible instead of using insulation materials).

Pending on the base hull material (steel | aluminium or GRP) sound deadening must be applied against the hull sides to reduce structure borne noise from the windows. For steel and aluminium, a constrained layer sound deadening can be used (SLP-COMP) along with multiple layers of Rockwool (or similar), void and sandwich sound reducing sandwich panels as hull and bulkhead liners (SLP-PANEL).

The entire accommodation throughout this Yacht is based on a box-in-box construction which means floating floor systems based on SLP-MER and SLP-PANEL, hull, and bulkhead liners along with partition walls are fixed mounted unto the floating floor and the upper part is flexible mounted by means of the ceiling gridwork.

This means that we do not have any rigid connection throughout this Yacht, everything is disconnected from the ship structure.

Salon area:

The deck structure above the engine room is covered with constrained layer sound deadening (SLP-COMP) and the flooring including engine room trunks are covered with sandwich sound reducing panels (SLP-PANEL).

The aft door includes an inflatable seal to reduce sound leakages.

The results as shown in table 1 and 2 are stunning and I think we may state that this Numarine 37XP Yacht is one of the quietest Yachts on the nowadays market.

Acoustic Privacy (cabin-to-cabin noise):

All partition walls are either coupled or decoupled using SLP-PANEL. This is a must as we achieve very low noise levels at anchor condition, acoustic privacy becomes very important issue.

HVAC noise:

HVAC (FCU noise) is a very important sound source especially at anchor condition and at night while sleeping. On board this Yacht we installed frequency controlled FCU along with sound absorbing tubes between the FCU and the air outlet boxes located at ceiling level.

The air inlet as well as the air outlet boxes are specially designed by Silent Line, a special labyrinth system is designed for both air inlet and outlet boxes combined with a low air speed at the openings. Inside the air inlet and outlet box SLP-FLAME is installed (no Armaflex as this is a closed cell foam, we need a open cell sound absorbing material).

The results are stunning as shown in table 2.

MATERIAL INDEX:

Material Index: