S-Line Comfort Plus Package (C.P.P)

Many Yachts, even nowadays in the range up to 80 feet, are noisy during transit and anchor condition. Over the years Silent Line assisted many Yacht Owner’s solving their annoying unnecessary noise | vibration problems.

Recently (2017) we assisted a Yacht Owner having problems sleeping at night having his stateroom forward of the engine room in which he had to deal with 53 dB(A) mainly emitted by the generator set. This is by far too high even on a Yacht in this size. We installed the S-Line (C.P.P) and ended up with 35 dB(A) emitted by both generator set running | AC operational and zero speed stabilizers.

Scope of Supply S-Line C.P.P:

High Volume generator set mounts:

The generator set is a serious sound source at anchor condition, not only air- borne noise but also structure- borne noise. How to solve this:

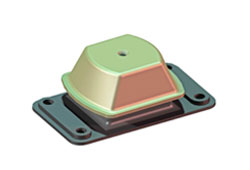

In the range from 9 kW and up the S-Line C.P.P contains high volume mounts (Marine approved) creating a double elastic mounting system without adding mass. These mounts are installed underneath the base (mostly wooden) plate of the generator set. The outcome is 10 dB(A) less noise in cabins adjacent to the engine room.

Engine Room Insulation Package:

Most of the engine rooms have limited insulation meaning foam and perforated plate. Foam is a nice and well-known product however the insulation value is zero (0).

This means it does not reduce noise from one room to the other room. Foam only absorbs the noise (reduce the noise inside the engine room) in case the foam is not covered with aluminium foil. This however is the case onboard many Yachts.

This means that absorption of the foam (covered with aluminium foil) also becomes zero (0).

What should be used:

In average the noise level inside the engine room with the generator set running is approx. 75 dB(A), with the main diesel engines running we end up with approx.

105 dB(A). It is important to keep the noise inside the engine room as much as possible and for that reason the S-Line C.P.P engine room insulation package contains:

- Closed RAL painted aluminium sandwich panels : click here for material datasheet

- Sandwich Foam – Mass Layer – Foam layer : click here for material datasheet

In average the noise level inside the engine room with the generator set running is approx. 75 dB(A), with the main diesel engines running we end up with approx.

105 dB(A). It is important to keep the noise inside the engine room as much as possible and for that reason the S-Line C.P.P engine room insulation package contains:

- Forward engine room bulkhead

- Overhead inside the engine room

- Hull sides

- Aft engine room bulkhead

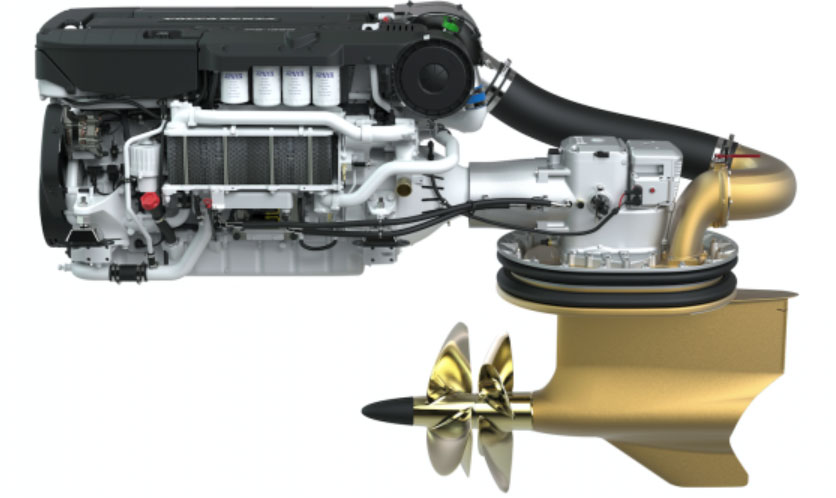

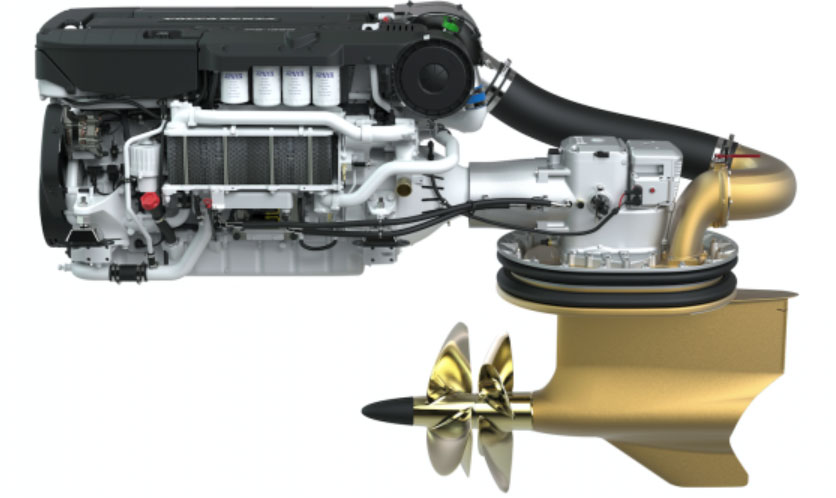

In most cases, onboard Yachts up to 80 feet, the main diesel engine and gearbox are flanged. The drive train (in most cases) does not contain a flexible coupling and thrust bearing. In case of a Volvo Penta I.P.S system it is more easy but still proper soft anti- vibration mounts are recommended capable of absorbing the trust.

Pending on the type of engine, output in kW and rpm and the gearbox ratio we will select the best anti- vibration mounts suitable for your Yacht. Upon request (recommended) if the space is available we offer the below shown highly flexible coupling with trust block.

SILENT LINE C.P.P FOR VOLVO PENTA I.P.S. SYSTEMS

Silent Line, in close consultation with Volvo Penta, is proud and honored to make some modifications to the above shown system knowing:

Anti-vibration mounts:

Pending on the requirements the standard Volvo Penta mounts do work however in case the client requires additional comfort from vibration point these mounts are “too stiff”.

With approval of Volvo Penta, we are able to select softer anti vibration mounts which ensure more comfort especially at idle and maneuvering speed. This however must be done in combination with the below mentioned topics. Only changing the mounts will not give the ultimate solution.

Cardan shaft:

A cardan shaft is, standard, installed between the engine and the pod. The cardan shaft gives an excellent flexibility however as it is a steel-to-steel connection it is “poor” from vibration | structure borne noise isolation meaning:

We isolated the engine from the ship foundation by improving the mounts however with the cardan shaft the vibrations are transmitted from the engine into the POD still ending up at the ship structure.

With approval of Volvo Penta, we changed the cardan shaft and installed a different coupling which offers us flexibility and isolation using a rubber element within the flexible coupling.

Exhaust Bypass System:

Many years ago, onboard the Zeelander Z44 as shown below, we updated the standard Volvo Penta exhaust system by adding a bypass system.

The openings in the back, as shown above, are used for the bypass system which operates from idle up to maneuvering speed and then automatically closes. This avoids vibrations due to exhaust gases coming out of the tail of the pod at idle up to maneuvering speed.

Nowadays Volvo Penta supplies this as well as an option.

Exhaust hose:

The above shown (black) thick exhaust hose which runs from the engine unto the pod is “too stiff” in combination with the afore mentioned modifications. By changing the mounts, install the special flexible coupling and bypass system we have to update this hose as well. Instead of the rubber hose we are using a SS pipe with flexible bellows on the engine side and pod side which gives us the flexibility we are looking for.

THE FIRST PROJECT:

The first project, in which we are not allowed to show any details, will be equipped with all above mentioned features as the client requested the latest technologies in the field of noise and vibration control. This project will be launched later this year, so stay tunes with us as we will give you the results after the sea trail.

SILENT LINE OFFERS INNOVATIVE CUSTOMER ORIENTED TAILOR-MADE SOLUTIONS IN THE FIELD OF NOISE AND VIBRATION CONTROL.

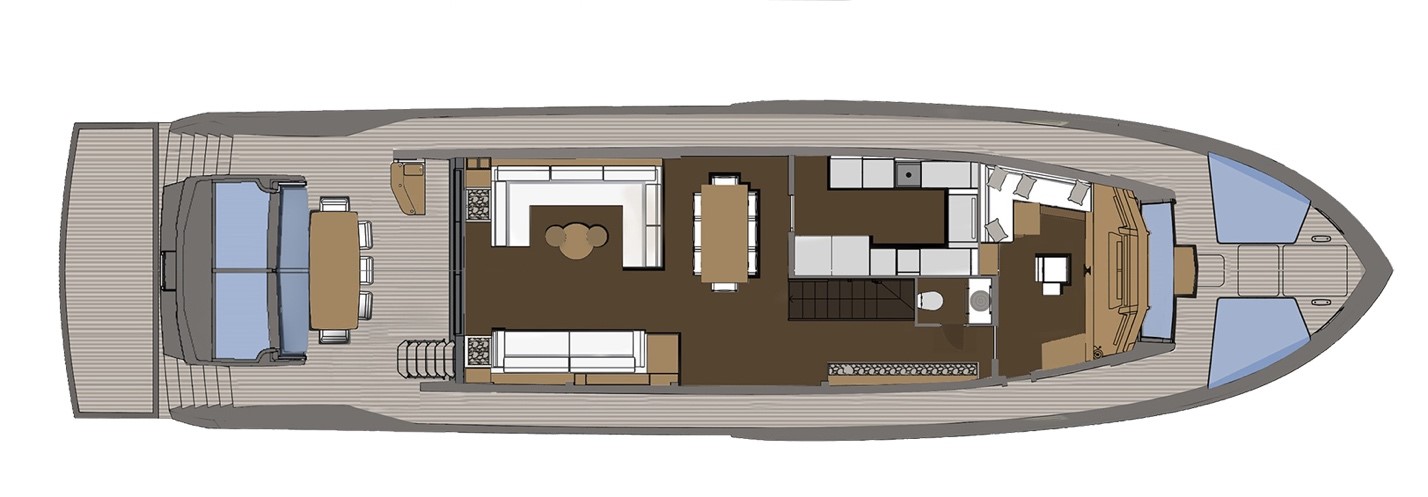

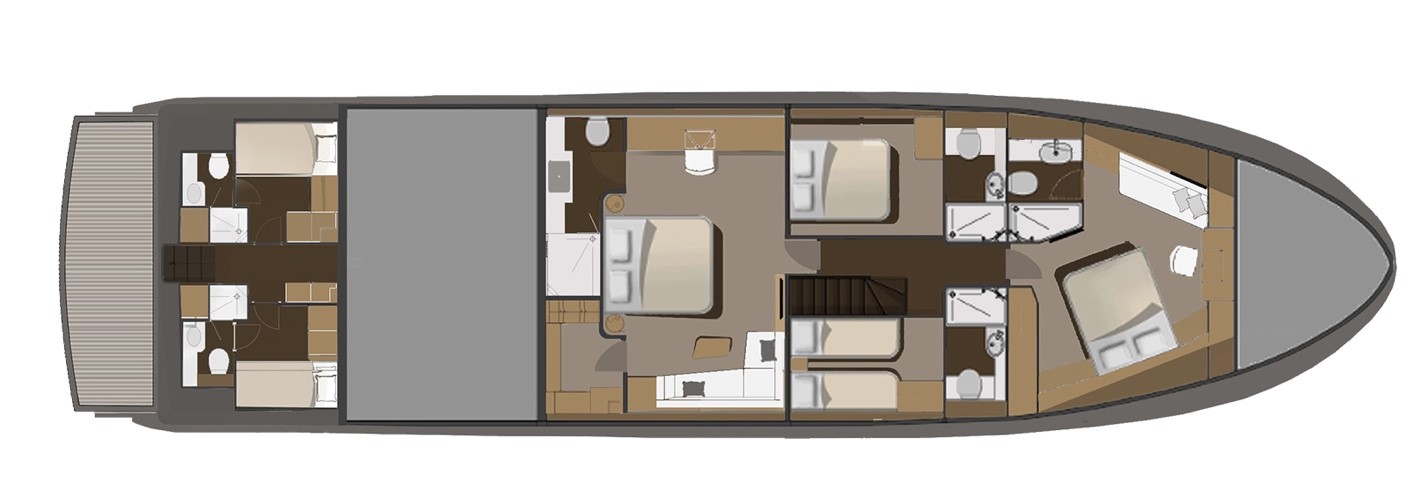

Numarine 26XP

Silent Line | Enjoy Your Luxury in Silence

INTRODUCTION:

As Silent Line we did many luxury Yachts in the range between 15 up to 25 meters however we would like to point out the successful Numarine XP edition as this Yacht contains most of the latest technologies in the field of noise and vibration control.

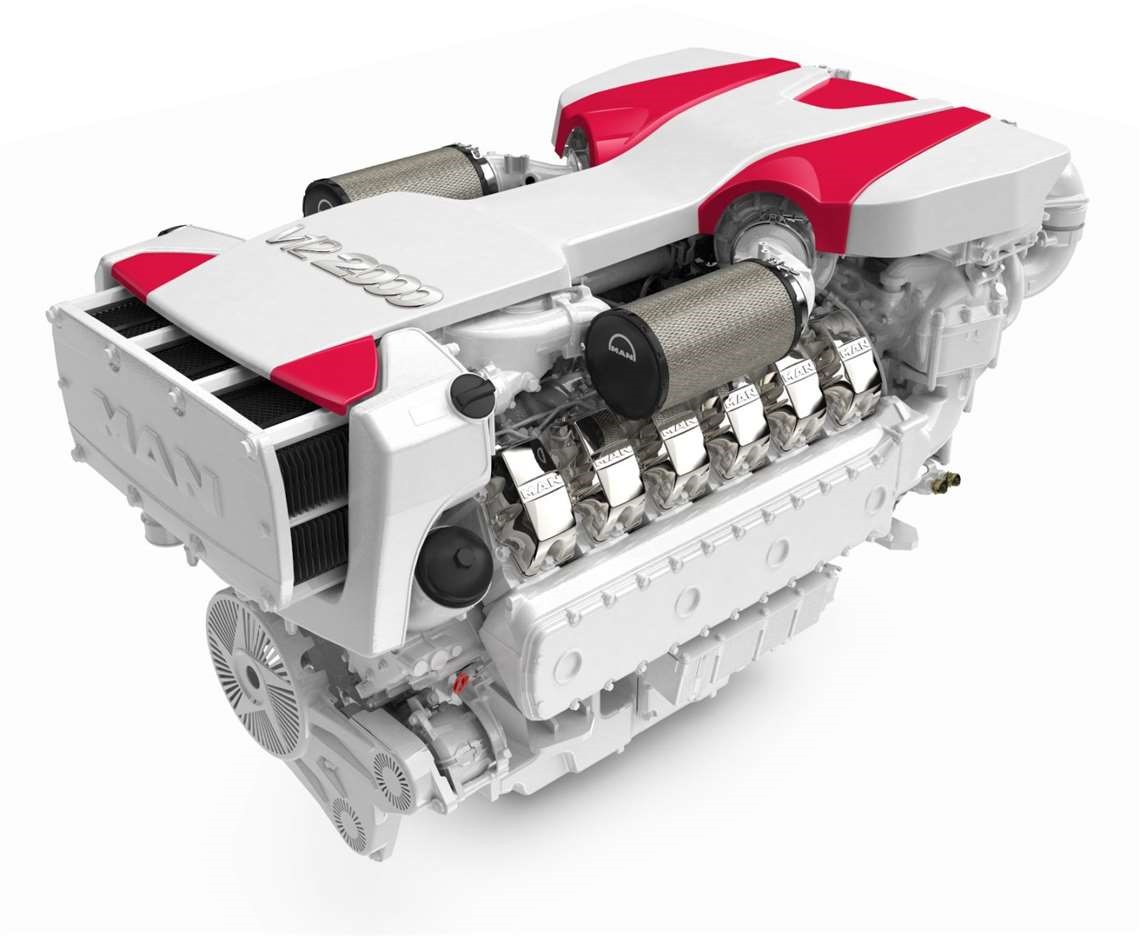

PROPULSION TRAIN:

The propulsion train, main engine and gearbox, are producing both airborne noise and structure borne noise (vibrations), which must be reduced in order to achieve comfortable noise and vibration levels in the accommodation areas and outer deck areas.

Before we go into details what has been done onboard this Yacht, we would like to point out what we achieved for both Cruising speed and Anchor condition.

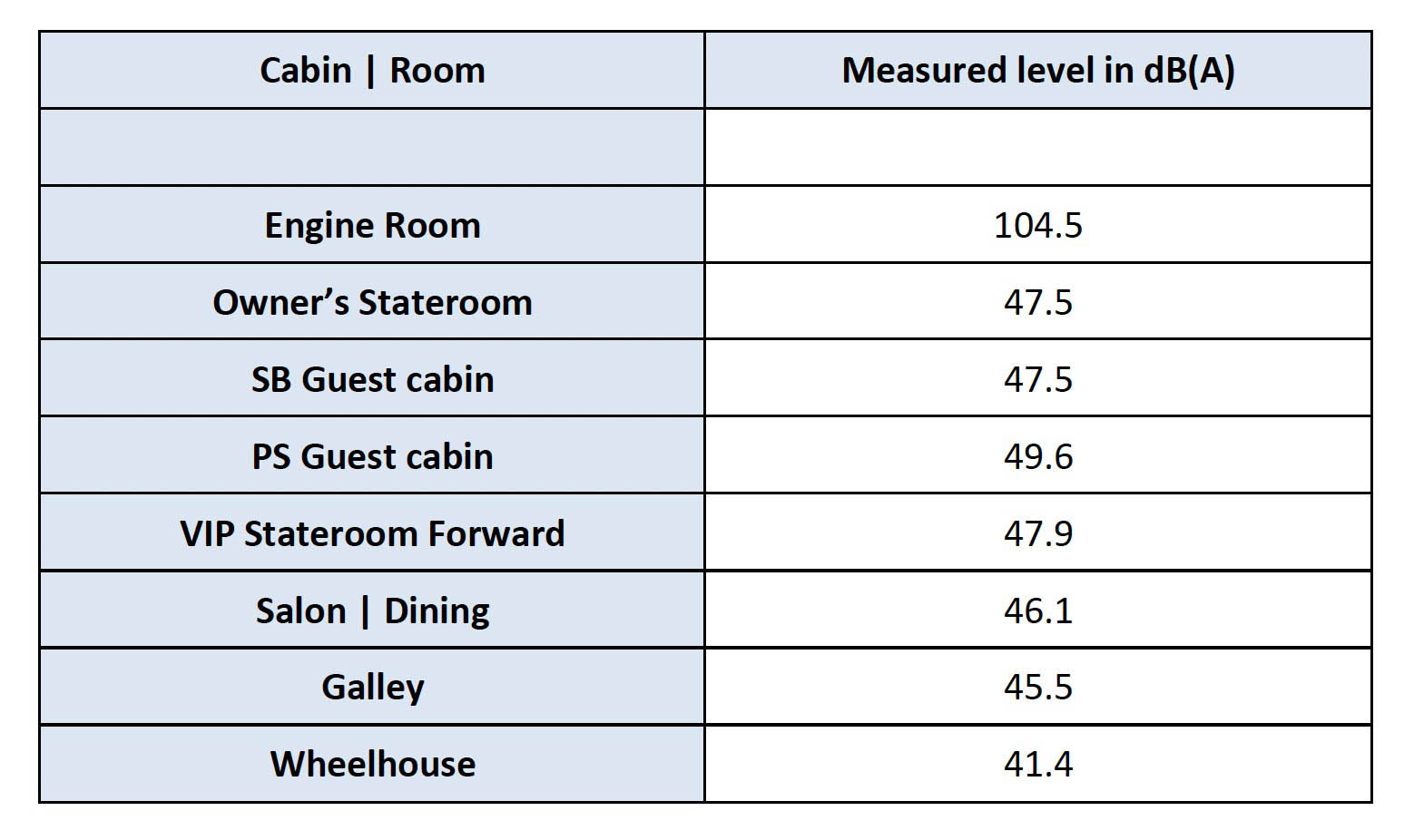

Table 1: Measured noise levels at Cruising speed (9 knots)

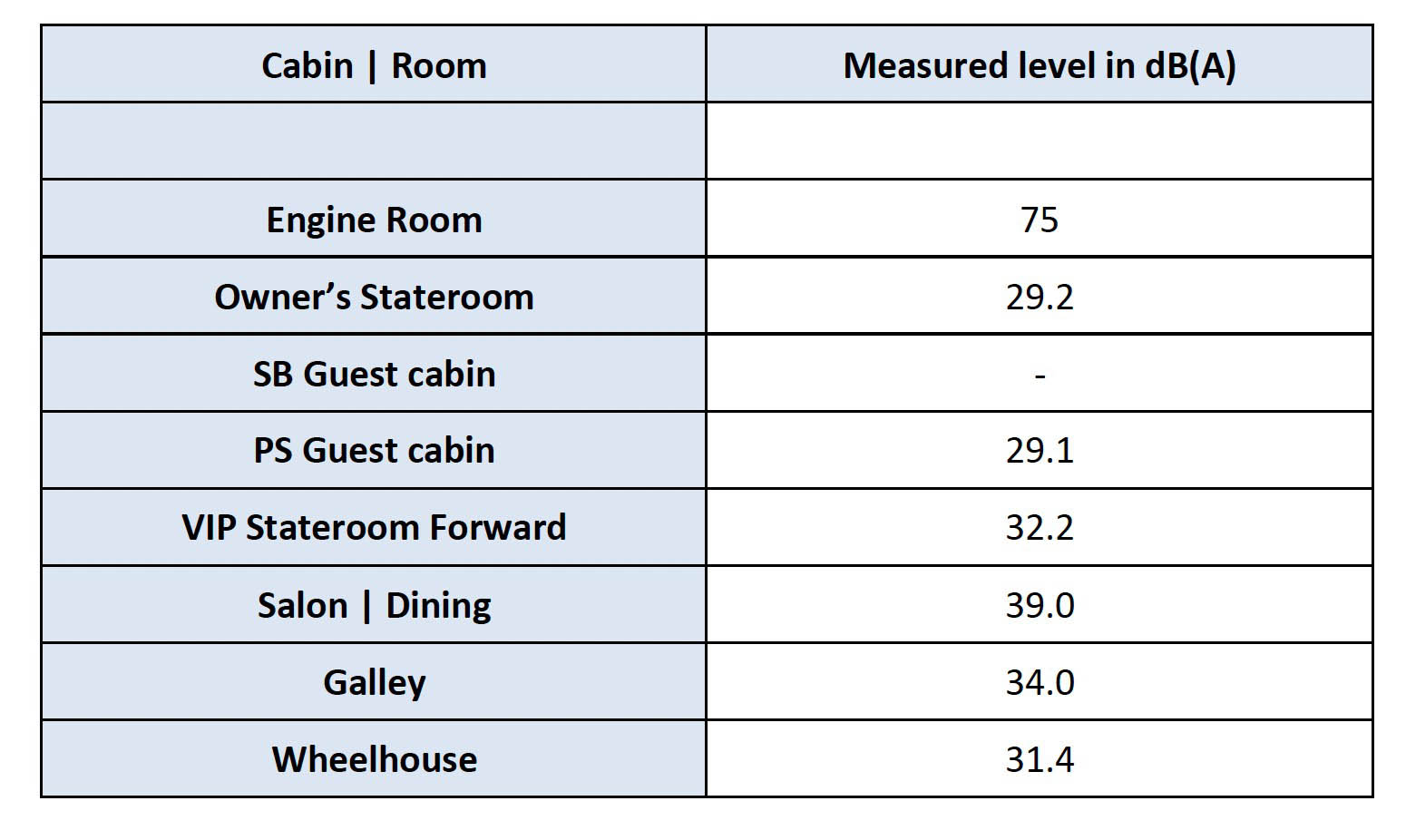

Table 2: Measured noise levels at Anchor condition (1 generator running | AC operational | Stabilizers operational)

These are stunning results and one of the reasons that the Numarine XP series is so popular in the market, Owners enjoy to spent time onboard and enjoy their Luxury in Silence.

What has been done by Silent Line:

Main engine and gearbox:

The shaft line does not include and thrust bearing which means that the thrust emitted by the propulsion propellers must be absorbed by the engine and gearbox elastic mounting system. This in case the engine and gearbox are flanged, with a free-standing gearbox the thrust must be absorbed by the gearbox only.

In case the main engine and gearbox are not flanged but both free standing, the same SLP-MOUNT IM2500-C mounts can be used at the free-standing gearbox. The SLP-MOUNT IM2500-C is capable to absorb the thrust emitted by the propulsion propellers. This means that a thrust block is not required.

The benefit of the SLP-MOUNT IM2500-C versus a semi elastic mounting system is, the SLP-MOUNT IM2500-C contains much more rubber and creates a much better isolation and therefor lower noise and vibration levels in the accommodation areas.

Gearbox noise:

By means of the afore mentioned SLP-MOUNT IM2500-C solution we created a perfect isolation between engine and gearbox versus the ship foundation however we have a second sound path knowing the propeller shaft which is connected to the gearbox. Mid and high frequency noise is transmitted through the shaft into the ship structure which creates an annoying gearbox noise inside the accommodation areas.

To solve and avoid this situation, a single rubber element (rubber flexible coupling) must be installed between the gearbox and the propeller shaft.

Generator sets:

Generator(s) are an important sound source mainly at anchor (in port) condition. Air borne noise, up to approx. 75 dB(A) for generator sets placed in a proper canopy (sound shield), is not a main issue if the engine room is well insulated (see chapter on engine room insulation).

In most cases structure borne noise is the dominant sound path, generator sets do have an elastic mounting system however in most cases the mounts are relative stiff which means limited isolation of structure borne noise emitted by the diesel engine.

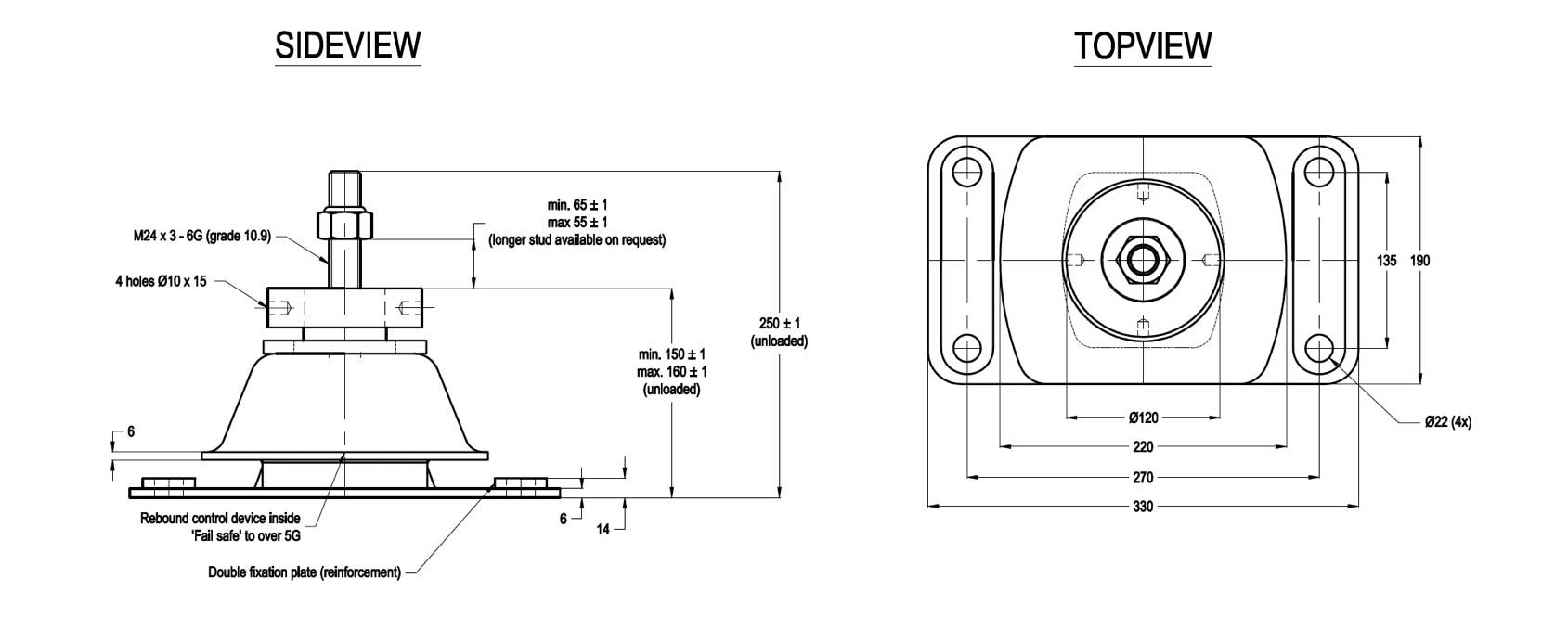

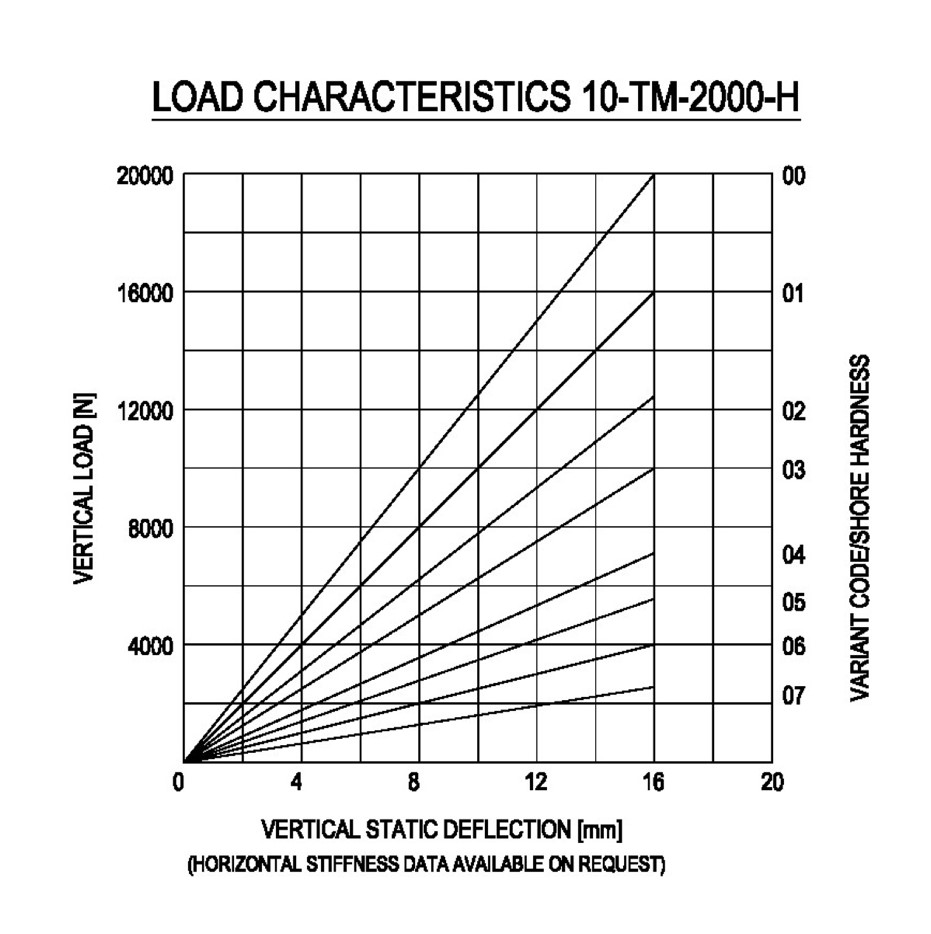

To solve this issue, we as Silent Line, recommend high volume additional mounts to be installed underneath the sub frame of the generator set. The benefit of the high-volume mounts, static deflection up to 10 mm, is that an additional heavy sub frame is avoided. With a standard double elastic mounting system, a heavy subframe is required to make the system work properly. By using high volume mounts, as shown below, such as heavy sub frame is not required.

Various rubber stiffnesses are available as shown in the above graph, Silent Line will do the necessary engineering studies to provide you with the best solution.

A stiff structure underneath the secondary elastic mounting is always required to achieve the best results, contact us if you have questions related to the structure you are using onboard your Yachts.

Engine room insulation:

A proper engine room insulation package is required mainly to block air borne noise emitted by the main diesel engines. As we prefer to keep the noise inside the engine room, perforated plate must be avoided. We prefer to use closed aluminium sandwich plates (SLP-SONIC) as shown below.

DI-BOND or ALUCO-BOND must be avoided as well, even as they are closed plate sandwich panels, they are very poor on noise reduction and mainly used in the building industry as decorative panels.

Between the structure and the above mentioned SLP-SONIC finishing plates we prefer to use a combination (sandwich) of isolation materials to reduce noise transmission in a frequency range from 31.5 Hz up to 8 kHz.

This can be achieved by using two outer layers of Rockwool with a mass layer in between (SLP-MASS) or a CE approved foam with SLP-MASS as core material. In case foam is used, aluminium finishing must be always avoided.

Alternative fire resistant (non-combustible) are available as well, please contact us if you have questions.

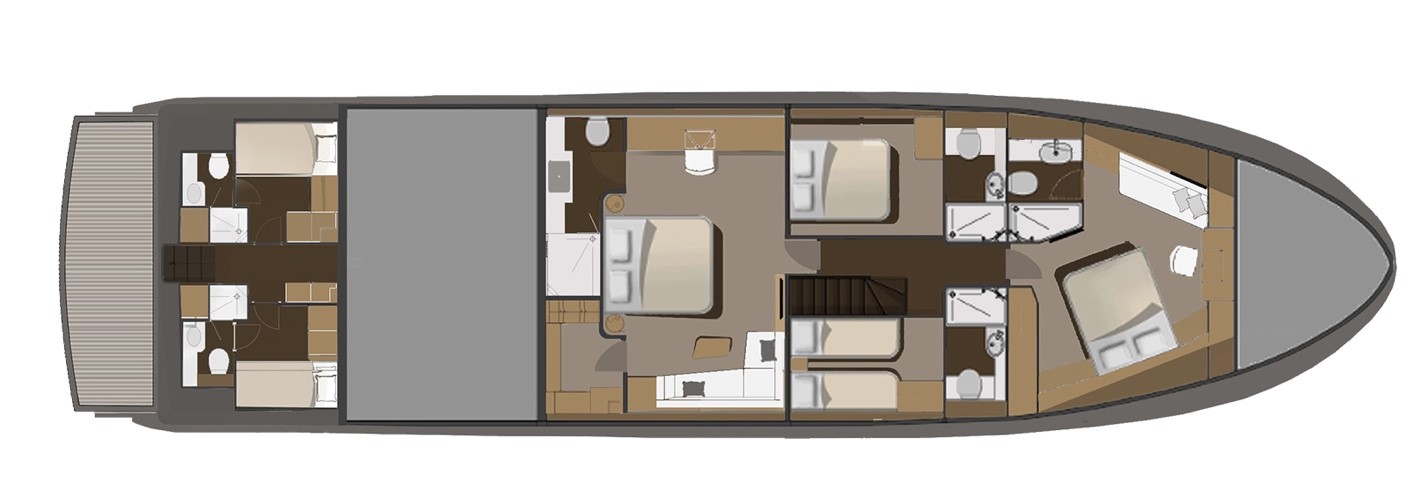

Accommodation areas:

The Master Stateroom, as shown above, is located forward of the engine room with a on suite bathroom and dressing area between the engine room and Master Stateroom. Upon request of the Owner, Silent Line performed additional noise and vibration studies to achieve the noise levels as shown in table 1 and 2.

As windows and portholes are the main sound source (related to the Master Stateroom), lightweight constrained sound deadening tiles (SLP-CLD) are applied unto the hull sides. SLP-FLAME (lightweight melamine foam) is used in the void between the hull and hull liners (hull liners are SLP-PANELS DA 550).

The bulkhead liner in the Master Bathroom and Dressing room is a sound reducing sandwich panel (SLP-PANEL DA 1050) as well as the floating floor system in the Master Stateroom using SLP-MER and SLP-PANEL DA 2150.

The results, as mentioned in table 1, are stunning and we strongly believe that this Yacht is one of the quietest Yachts in the world in the range.

In the VIP Stateroom we applied SLP-CLD tiles at the shine to reduce radiated structure borne noise due to the impact of waves and water flow while cruising.

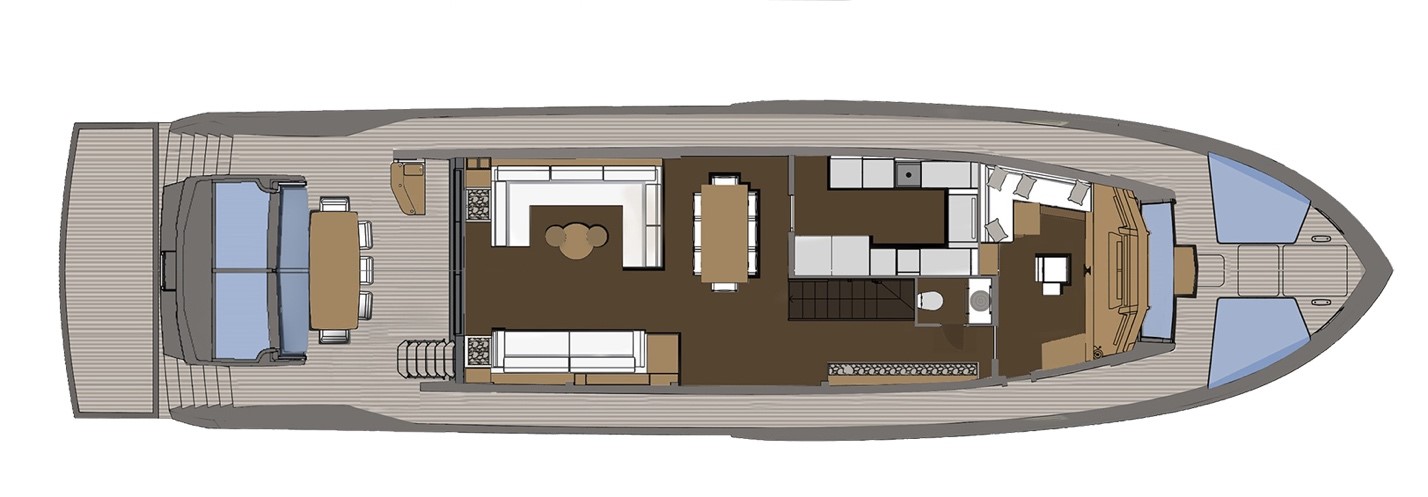

The Salon area along with the Dining area are important areas to relax while cruising or spent time in the evening while on anchor. As the Salon area is partly over the engine room special attention is given to the flooring system which contains SLP-MER and SLP-PANEL DA 2150 giving the comfort we are looking for. The noise results are presented in table 1 and 2.

HVAC noise:

HVAC (FCU noise) is a very important sound source especially at anchor condition and at night while sleeping. On board this Yacht we installed frequency controlled FCU along with sound absorbing tubes between the FCU and the air outlet boxes located at ceiling level.

The air inlet as well as the air outlet boxes are specially designed by Silent Line, a special labyrinth system is designed for both air inlet and outlet boxes combined with a low air speed at the openings. Inside the air inlet and outlet box SLP-FLAME is installed (no Armaflex as this is a closed cell foam, we need a open cell sound absorbing material).

The results are stunning as shown in table 2.

MATERIAL INDEX:

Material Index: