SILENTILE

Featured Properties

• Excellent acoustic performance in low frequencies i.e. 60-100 MHz

• The lightest and most effective damping performance

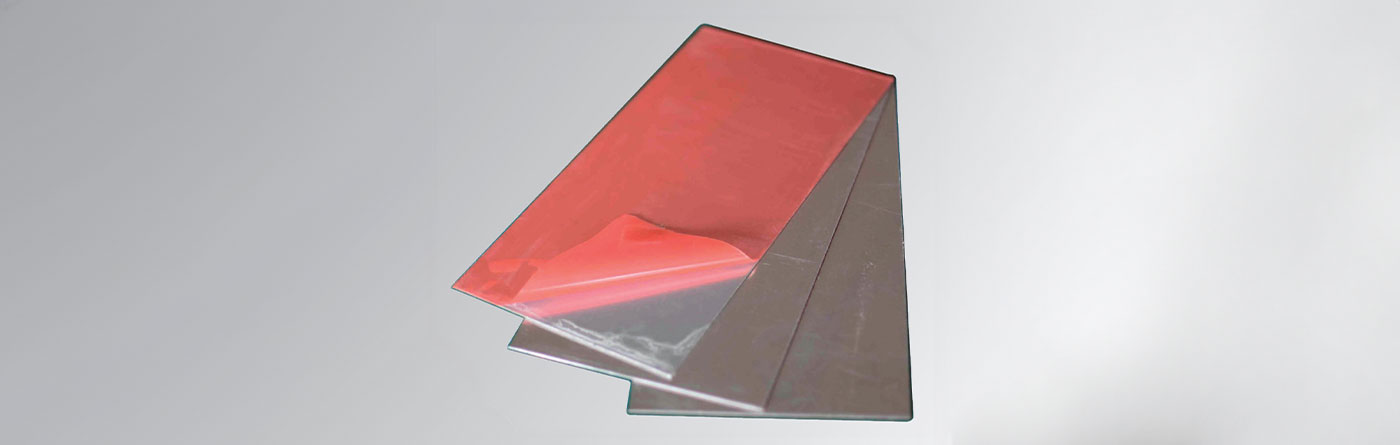

• Fast and easy application, just peel and stick on

• For aluminium, steel, fibre-reinforced plastic, and carbon composite surfaces

• Operation temperature range of -20 C° to 120 C°

• SilenTile® HX-A, Aluminium for aluminium, fibre-reinforced plastic, and carbon composite surfaces

• SilenTile® HX-S, Steel for steel surfaces

• Nautical applications damping of hull, bulkhead, and deck

• Automotive applications damping of body panels such as doors, roof, fenders and truck

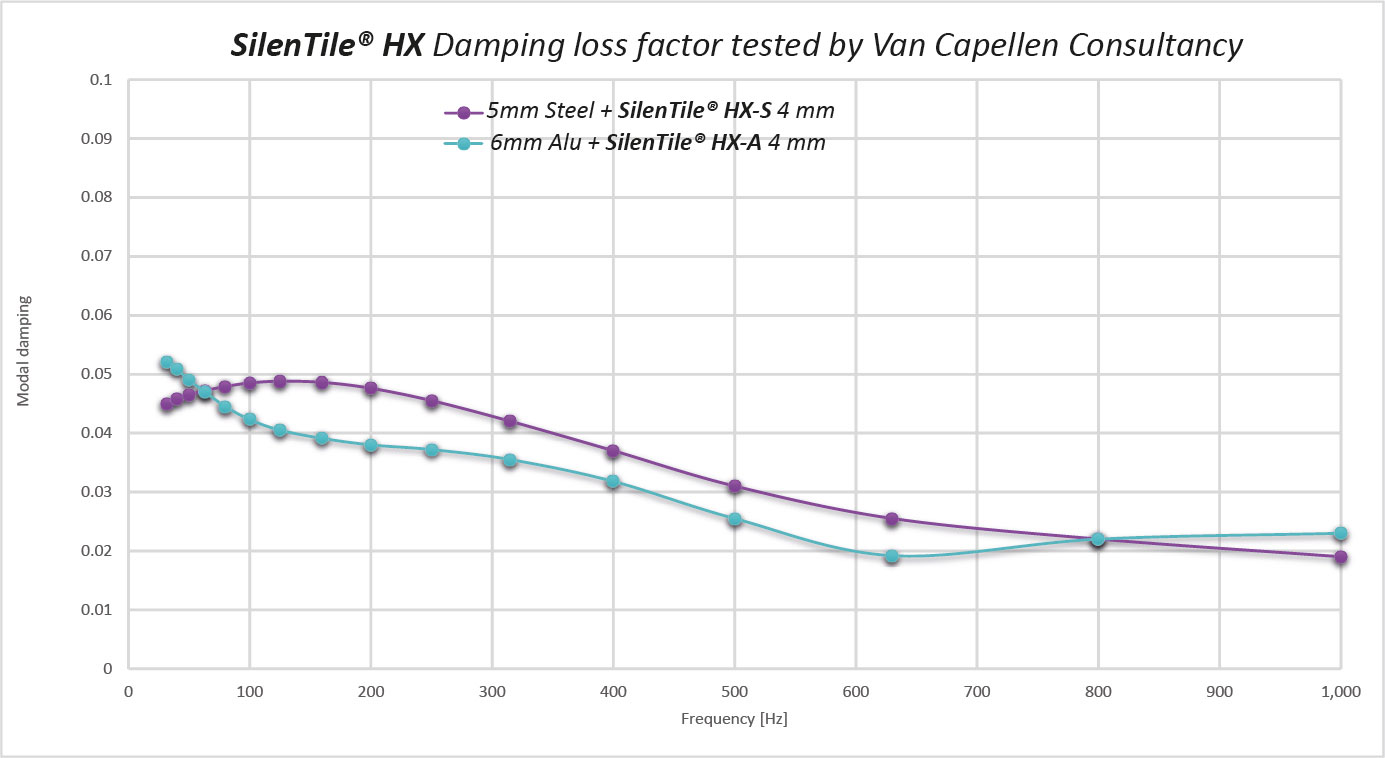

SilenTile® HX

SilenTile® HX is a multi-layer constraint type, structure borne noise and vibration damping material, designed to reduce the vibrations and can realise easiness of processing and a low cost at the same time, in aluminium, steel, fibre-reinforced plastics, and carbon composite surfaces.

Using the latest polymer alloy technology SilenTile® HX has a unique high viscous damping and isolation properties over a wide temperature range of -20 C° to 120 C°.

The self-adhesive technology provides the ease of installation and enables the product to withstand temperatures up to 120 C° without delaminating from the substrate (short term exposure only). In addition, SilenTile® HX had excellent adhesion to primed steel, lacquered steel, aluminium, and low surface energy substrates such as polypropylene, PVC and polyethylene.

SilenTile® HX has a wide range of application area, suitable for nautical applications e.g. damping of hull, bulkhead, and deck; and for automotive applications such as damping of body panels e.g. doors, roof, fenders, and truck.

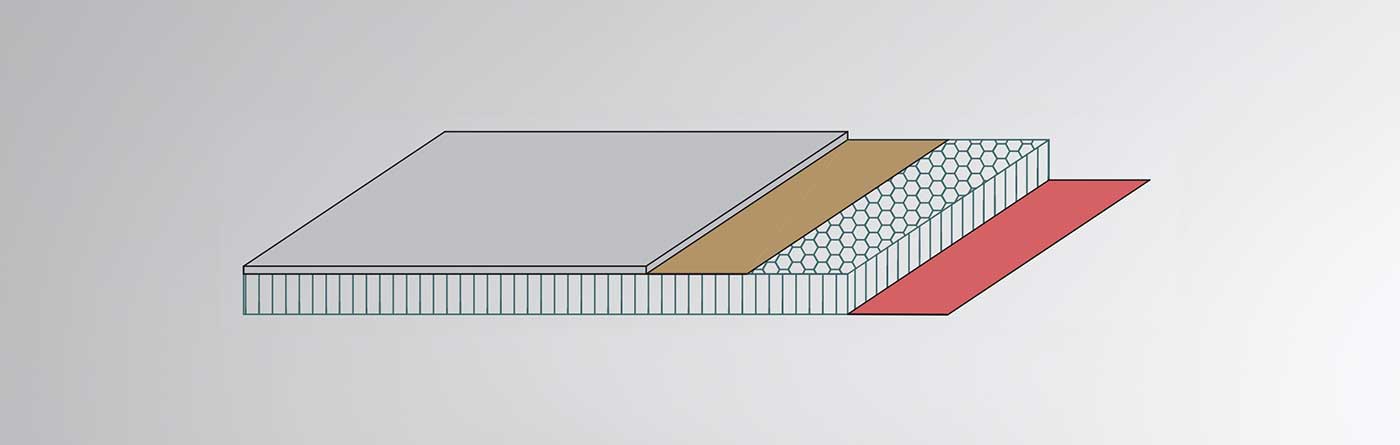

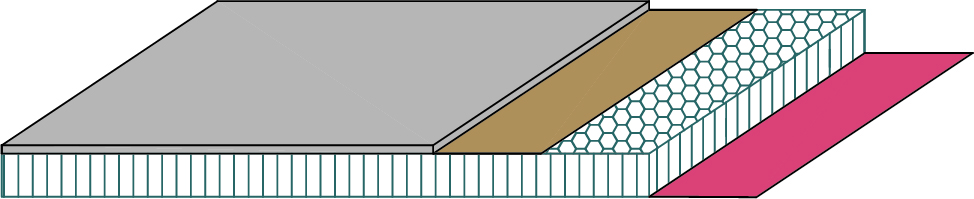

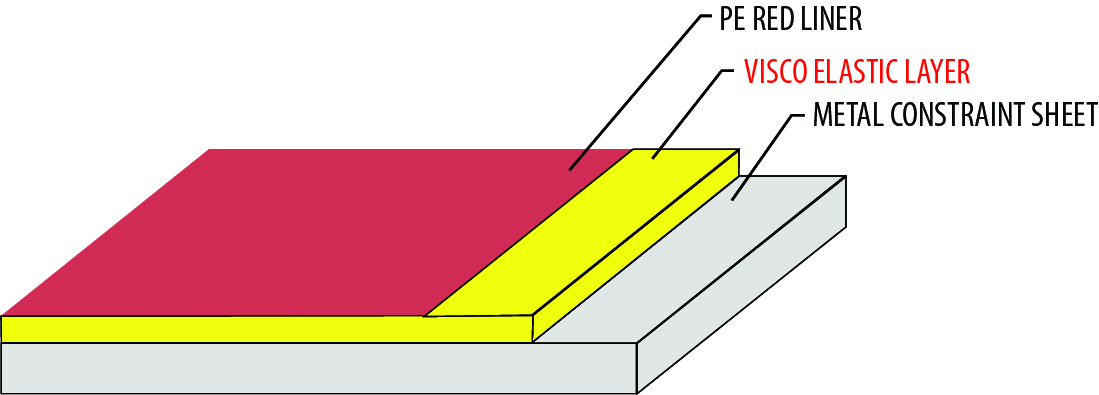

Constraint Sheet

0.5mm or 1.00mm Aluminium SilenTile® HX-A or

0.5mm to 1.00mm Steel SilenTile® HX-S

(depending on the application surface and preference)

Application

Surface preparation:

To obtain optimum adheasion, the bonding surfaces must be well unified, clean and dry. Typical surface cleaning solvent is a 50:50 mixture of isopropyl alcohol (IPA) and water. For heavy oils or grease, a degreaser or solvent-based cleaner may be required and should be followed by cleaning with IPA/water.

Abrading a surface, followed by cleaning with IPA/water, can remove heavy dirt or oxidation, and can increase surface area to improve adhesion. Porous surfaces and fibered materıals need to be sealed to provide a unified surface, and for unique materials such as glass and glass-like materials, copper and copper containing metals and plastics or rubber, special surface preparation may be required.

Application method:

Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure develops better adhesive contact and helps improve bond strength.

Peel of the release liner and apply the tile onto the unified, clean, and dry substrate, apply firm hand pressure, or better use a roller to push the damping tile onto the substrate.

Minimum coverage: 80% of total area.

Recommended application temperature: above 10 C°.

Viscoelastic Damping Glue

Honeycomb Core

3.5 mm core thickness fire-retardant Honeycomb

High Performance Pressure Sensitive Tape

Dimensions and weight

For SilenTile® HX-A: 4.8mm x 100mm x 200mm

Weight per unit area: 2.54 kg/m²

For SilenTile® HX-S: 4.8mm x 100mm x 200mm

Weight per unit area: 5.41 kg/m²

Custom dimensions are available on request.

(Max. dimensions 930mm x 2000mm)

Tests and Certificates

Cetified according to the IMO, 2010 FTP Code, Part 2, Smoke and Toxicity Test where a material is required not to be capable of producing excessive quantities of smoke and toxic products or not to give rise to toxic hazards at elevated temperatures. Also certified according to the IMO, 2010 FTP Code, Part 5, Surface Flammability Test where a product is required to have a surface with low flame-spread characteristics, to be not readily ignitable.

Featured Properties

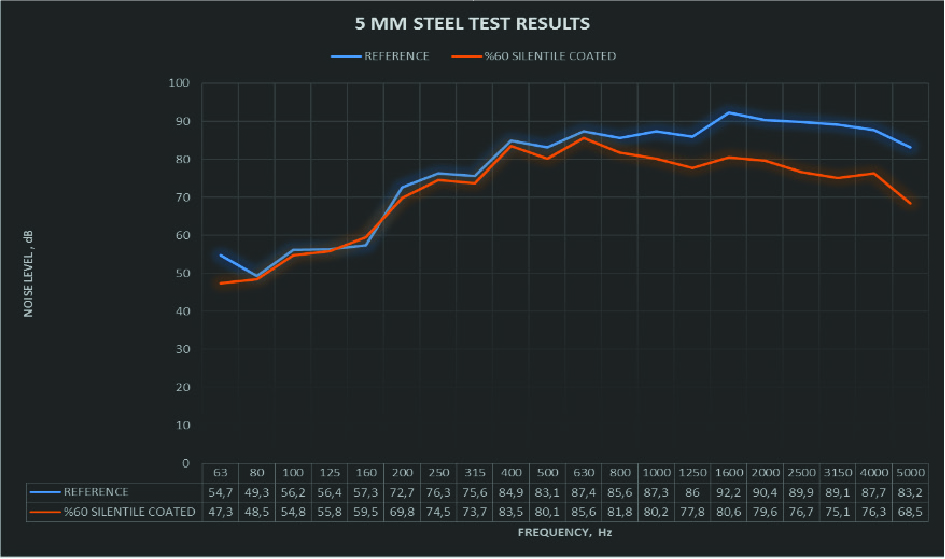

• Reduce panel vibration and resonant noise effectively

• Increase sound transmission loss

• Low installation cost – just peel and stick on

• Thin and light weight damping tiles

• Easy application

• High damping efficiency for thick metal plates

• Excellent adhesion to most substrates

• Extended operating temperature range (-20 120 C)°

• Non-toxic

• Good flexibility/softness for curve line and good to fill the gap

• Good weatherability, Solvent resistance

Description

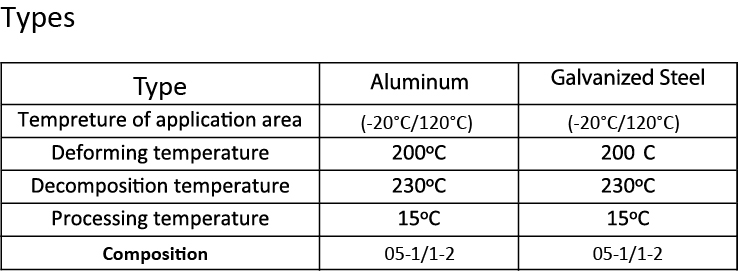

SilenTile® is self-adhesive constrained layer vibration damping tile. Using the latest polymer alloy technology, SilenTile® has a unique viscoelastic polymer blend designed to provide high viscous damping and isolation properties over a wide temperature range (-20°C/120°C) with built-in self-adhesive technology. The built-in self-adhesive provides for ease of installation. This unique adhesion enables the product to withstand temperatures up to 120ºC without delaminating from the substrate (short term exposure only). In addition, SilenTile® has excellent adhesion to primed steel, lacquered steel, aluminium and low surface energy substrate such as polypropylene , PVC and polyethylene.

SilenTile® is designed to damp the low frequency structure-borne noise as well as increasing the sound transmission loss. SilenTile® is specially developed to provide sufficient damping for thick substrates such as steel, aluminium, plastic and GRP composites

Material Characteristics

Core layer of SilenTile® is made of a viscoelastic layer. When the composite sheet subject to flexural vibrations, there is slight relative movement between the cover sheets which results in periodic shear deformations in the viscoelastic layer. The internal friction generates in the viscoelastic layer and causes vibrational energy to be “ lost/converted” as mechanical energy, i.e. it is converted into heat; this dampens vibration in the composition.

Withins working range( 25-80 ºC) and the material achieves optimal vibration damping through a correspondingly high loss facto

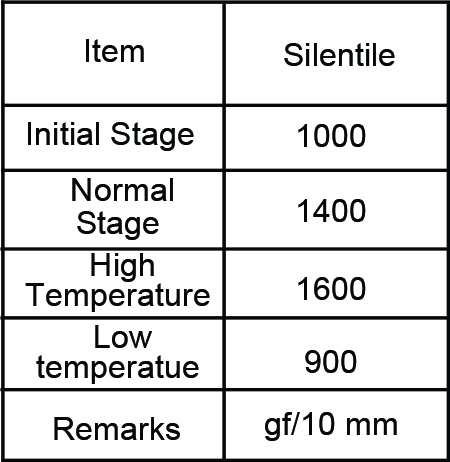

Adhesion

The force required to pull a strip of tape from a surface at a 180degree angle, at the rate of 300±10㎜ per minute.

Instrument: Peel adhesion tester

Speed: 300±10mm/Min

Tape width: 10mm

Backing: 25 micron polyester film

1) Inıtial Stage: 30mins after adhesion, measure at room temperature

2) Normal State: 24hrs after adhesion, measure at room temperature

3) High Temperature aging: 40mins after adhesion at 80° measure

3) Low Temperature aging: 30mins after adhesion at -30° measure

Applications

It is one of the most suitable damping material for weight sensitive applications, such as automotive, boats, buses and trains.

High efficiency vibration damping and isolation material for reducing impact or vibration induced noise:

Vibration damping for thick metal substrates, typically from 4mm to 12mm thick

Ship bulkheads, decks, hulls and other marine applications Vibration damping for thick metal plates in locomotives, trains and trucks, enclosure, metal housing

Installation

Surface preparation:

The surface must be dry, free of oil, dust, grease, rust and other contaminants.

Application method:

Peel off the release liner on the back of the damping tile and apply the tile onto the substrate. After the initial contact, apply firm hand pressure or use a roller to push the damping tile onto the substrate. The damping tile must be in full contact with the substrate and free of any trapped air bubbles.

The damping tile is designed to be re-positionable within 24 hours after application. The damping tiles will reach their full bond strength after 24 hours.

Minimum coverage:

70% of total area.

Recommended application temperature:

Above 10°C.

DOWNLOAD PDF